Last Updated on 2025-07-21 by Anze

As a seasoned leather perforating tool manufacturer with two decades of expertise, we have been at the forefront of the leather processing industry, delivering top-notch perforating tools that meet the diverse needs of our clients. Our journey as a leather perforating tool manufacturer has been marked by a commitment to innovation, quality, and customer satisfaction. In this blog, we will explore the history, processes, and future prospects of our company as a leading leather perforating tool manufacturer.

The Genesis of a Leather Perforating Tool Manufacturer

Our story as a leather perforating tool manufacturer began in [Year], when our founder, with a passion for leather craftsmanship and a vision to revolutionize the industry, established our company. With a focus on precision and innovation, we quickly gained recognition as a reliable and efficient leather perforating tool manufacturer, catering to the needs of various leather goods manufacturers.

Early Years and Milestones

In our early years, we faced numerous challenges, including developing perforating tools that could handle different types of leather materials and achieve intricate patterns. Through relentless research and development, we were able to overcome these challenges and introduce groundbreaking leather perforating tools that set new standards in the industry.

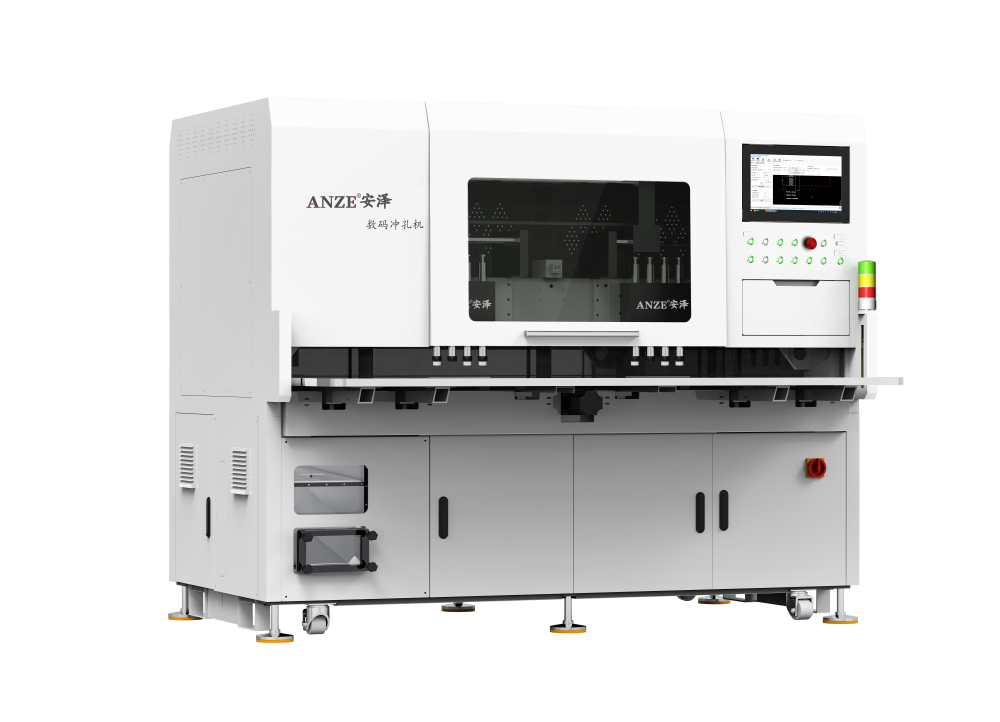

As a leather perforating tool manufacturer, we celebrated several milestones, including the development of our first CNC-controlled perforating machine, which significantly improved production efficiency and accuracy. This was a turning point for our company, as it marked the beginning of our journey towards becoming a leader in the leather perforating tool market.

Innovation and Growth

Innovation has always been at the core of our company’s philosophy as a leather perforating tool manufacturer. Over the years, we have continuously invested in research and development, striving to stay ahead of the curve and meet the ever-evolving needs of the leather industry.

Our dedication to innovation has resulted in the development of various leather perforating tools, each designed to cater to specific requirements, such as different leather thicknesses, pattern complexities, and production volumes. We have also incorporated advanced technologies, such as laser cutting and automation, to further enhance the capabilities of our leather perforating tools.

The Art and Science of Leather Perforating Tool Manufacturing

As a leather perforating tool manufacturer, our process is a blend of art and science, requiring a deep understanding of leather materials, design principles, and manufacturing techniques. In this section, we will delve into the various stages of our manufacturing process, highlighting the key aspects that make our leather perforating tools stand out in the market.

Material Selection

The quality of the leather perforating tool largely depends on the materials used in its construction. As a leather perforating tool manufacturer, we carefully select high-quality materials that can withstand the rigors of the perforating process while maintaining precision and durability.

We work closely with our suppliers to ensure that we have access to the best materials, such as high-strength steels and specialized coatings, which enhance the performance and lifespan of our leather perforating tools.

Design and Development

The design phase is crucial in the manufacturing process of leather perforating tools. Our team of experienced designers and engineers collaborates closely with clients to understand their specific requirements and develop customized solutions that meet their needs.

Using advanced CAD/CAM software, we create detailed designs and simulations of the leather perforating tools, allowing us to visualize and optimize the performance before the manufacturing process begins. This ensures that our tools are not only precise and efficient but also visually appealing and ergonomic.

Manufacturing and Quality Control

Once the design is finalized, we proceed to the manufacturing phase, where our skilled craftsmen utilize state-of-the-art machinery and techniques to bring the leather perforating tools to life. Each tool undergoes a rigorous quality control process to ensure that it meets our high standards of precision, durability, and performance.

As a leather perforating tool manufacturer, we take pride in our craftsmanship and strive for perfection in every aspect of our manufacturing process. This commitment to quality has earned us a reputation as a reliable and trusted partner in the leather industry.

Applications and Markets for Leather Perforating Tools

The versatility and precision of our leather perforating tools make them suitable for a wide range of applications and markets. In this section, we will explore some of the key areas where our tools are used and the benefits they offer to our clients.

Automotive Industry

The automotive industry is one of the largest markets for leather perforating tools. Car seats, steering wheel covers, and other interior components often require perforations for aesthetic and functional purposes. Our tools enable manufacturers to achieve intricate patterns and designs, enhancing the overall look and feel of the vehicle’s interior.

As a leather perforating tool manufacturer, we understand the unique requirements of the automotive industry and offer a range of tools that cater to these needs, ensuring precision, efficiency, and reliability in the production process.

Furniture and Upholstery

The furniture and upholstery industry is another significant market for leather perforating tools. Perforations in leather furniture not only add a touch of elegance but also improve air circulation, making the seating more comfortable. Our tools enable manufacturers to create a variety of patterns and designs, catering to the diverse tastes and preferences of their customers.

As a leather perforating tool manufacturer, we work closely with furniture and upholstery manufacturers to develop customized solutions that meet their specific requirements, ensuring that their products stand out in the competitive market.

Fashion and Accessories

The fashion and accessories industry also benefits from the precision and versatility of our leather perforating tools. From handbags and wallets to shoes and belts, perforations can add a unique and stylish touch to leather products. Our tools enable designers to experiment with different patterns and textures, creating one-of-a-kind pieces that captivate consumers.

As a leather perforating tool manufacturer, we stay abreast of the latest fashion trends and offer a range of tools that cater to the ever-changing needs of the industry, ensuring that our clients stay ahead of the competition.

Sustainability and Social Responsibility as a Leather Perforating Tool Manufacturer

As a responsible leather perforating tool manufacturer, we recognize the importance of sustainability and social responsibility in our operations. We are committed to minimizing our environmental impact and promoting ethical practices in the leather industry.

Environmental Initiatives

We have implemented various environmental initiatives in our manufacturing process, such as reducing waste, conserving energy, and using eco-friendly materials. We also encourage our clients to adopt sustainable practices, promoting the use of recyclable materials and energy-efficient machinery.

As a leather perforating tool manufacturer, we are constantly exploring new ways to reduce our carbon footprint and contribute to a greener future. We believe that by working together, we can make a significant impact in preserving our planet for future generations.

Ethical Practices

We are committed to promoting ethical practices in the leather industry, ensuring that our materials are sourced from responsible suppliers who adhere to strict animal welfare standards. We work closely with our suppliers to ensure that they comply with international regulations and guidelines, promoting a fair and transparent supply chain.

As a leather perforating tool manufacturer, we believe that it is our responsibility to contribute to a more ethical and sustainable leather industry, setting an example for others to follow.

Customer Support and After-Sales Service

At Anze, we understand the importance of customer support and after-sales service in building long-lasting relationships with our clients. As a leather perforating tool manufacturer, we offer comprehensive support and assistance, ensuring that our clients receive the best possible experience when working with us.

Technical Support

Our team of experienced technicians is available to provide technical support and assistance to our clients, helping them troubleshoot any issues they may encounter with our leather perforating tools. We offer remote support, on-site visits, and training sessions to ensure that our clients are equipped with the knowledge and skills to operate our tools efficiently and effectively.

Spare Parts and Maintenance

We understand that regular maintenance and the availability of spare parts are crucial in keeping our leather perforating tools running smoothly. As a leather perforating tool manufacturer, we offer a wide range of spare parts and maintenance services, ensuring that our clients can quickly and easily replace any worn or damaged components.

Our maintenance services include regular inspections, cleaning, and lubrication of the tools, as well as repairs and overhauls when necessary. We strive to minimize downtime and ensure that our clients’ production processes run smoothly and efficiently.

Customer Feedback

We value the feedback of our clients as it helps us improve our products and services. As a leather perforating tool manufacturer, we encourage our clients to share their experiences and suggestions with us, enabling us to continuously evolve and meet their ever-changing needs.

We regularly conduct customer satisfaction surveys and gather feedback through various channels, such as email, phone, and social media. This feedback is used to improve our products, services, and overall customer experience, ensuring that we remain the preferred.

Some models are shipped assembled in the factory. Large equipment is packaged in several parts and an installation manual is provided. All equipment is equipped with user manuals in Chinese and English.

Customers can send someone to anze factory to learn or we send technical experts to provide on-site training

The machine should be fixed on a stable table and the environment should be kept clean and tidy to avoid contact with dust, static electricity, humidity, and chips to cause parts failure.

We have an experienced after-sales team 24h online service and a completafter-sale system. Factory trainning support, Video technical available to service machinery overseas. support, online support, Engineers.

Of course we do welcome to visiting our company and have a face-to-face communication to advance mutual business.

Lead time varies depending on the order quantity and customization, typically ranging from 7 to 10 working days.If it is a custom leather punching machine order, it takes 1-2 months.