leather perforating tool

Manufacturer

As a top leading leather perforating tool manufacturer in China, we focus on R & D of perforation leather solutions with 20 years experiences !

Global top leather perforating tool manufacturer

As a seasoned leather perforating tool manufacturer with two decades of expertise, we have been at the forefront of the leather processing industry, delivering top-notch perforating tools that meet the diverse needs of our clients. Our journey as a leather perforating tool manufacturer has been marked by a commitment to innovation, quality, and customer satisfaction.

Our story as a leather perforating tool manufacturer began in 2006 when our founder, with a passion for leather craftsmanship and a vision to revolutionize the industry, established our company. With a focus on precision and innovation, we quickly gained recognition as a reliable and efficient leather perforating tool manufacturer, catering to the needs of various leather goods manufacturers.

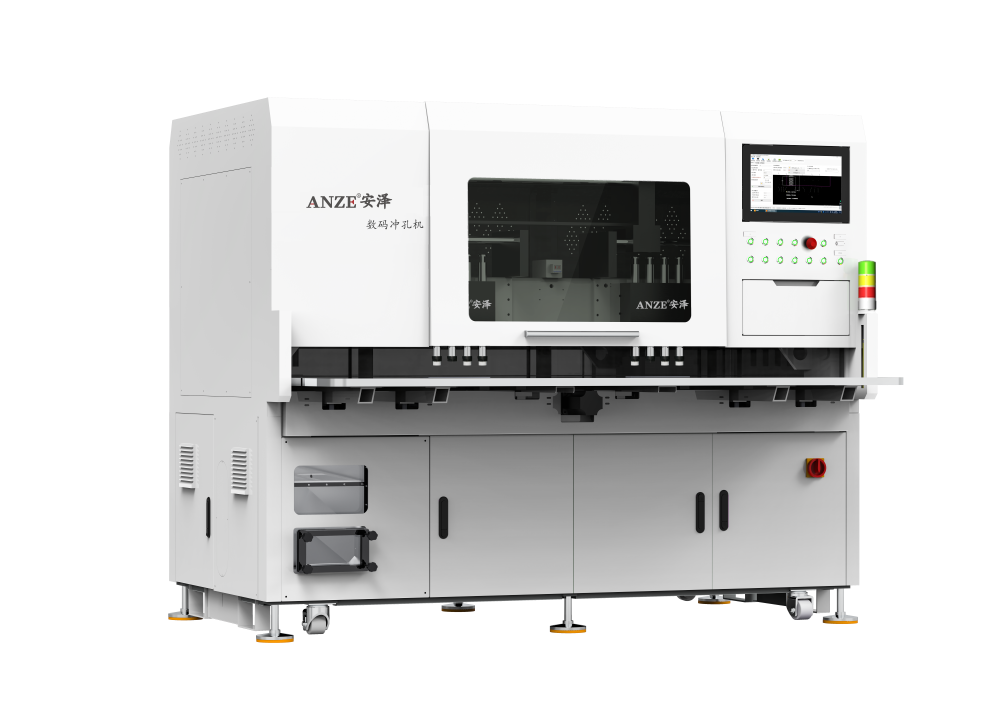

CNC Technology in leather perforating machine

In our early years, we faced numerous challenges, including developing perforating tools that could handle different types of leather materials and achieve intricate patterns. Through relentless research and development, we were able to overcome these challenges and introduce groundbreaking leather perforating tools that set new standards in the industry.

As a leather perforating tool manufacturer, we celebrated several milestones, including the development of our first CNC-controlled perforating machine, which significantly improved production efficiency and accuracy. This was a turning point for our company, as it marked the beginning of our journey towards becoming a leader in the leather perforating tool market.

leather Perforating tool manufacturer

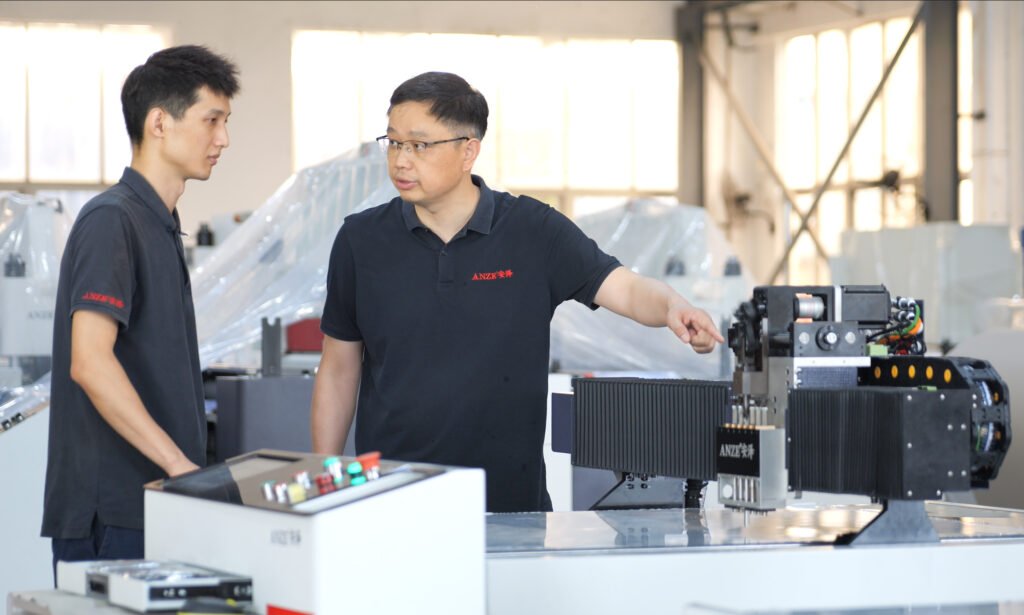

With an experienced and skilled team, we are familiar with all kinds of material characteristics and processing technology, and can customize the design according to customer needs.

As a key leather perforating tool manufacturer, we focus on quality control. From the procurement of raw materials to the shipment of finished products, each link is strictly implemented in accordance with the ISO9001 quality management system, and equipped with perfect testing equipment and processes.

Top Leather Punching tool Manufacturer

Our journey began with a vision to revolutionize the leather industry by creating cutting-edge punching equipment that not only met but exceeded the needs of our customers. Through relentless dedication and a commitment to quality, we have established ourselves as a trusted partner to numerous renowned brands, catering to their specific requirements with precision and expertise.

Founder Mr. Xu Zesheng founded Anze Automation Equipment Co., LTD., initially focused on the research and development and production of complete control systems of machinery industry, with strong technical strength and unremitting efforts, successfully provided many customers with high quality software and complete sets of electronic control systems.

The expansion of the company and the expansion of the scale, upgrade to 2200 square meters of intelligent factory

Introduced the CNC leather punching machine A2-D, which is three times faster than similar products with a punching speed of up to 600 holes per minute, becoming the industry leader.

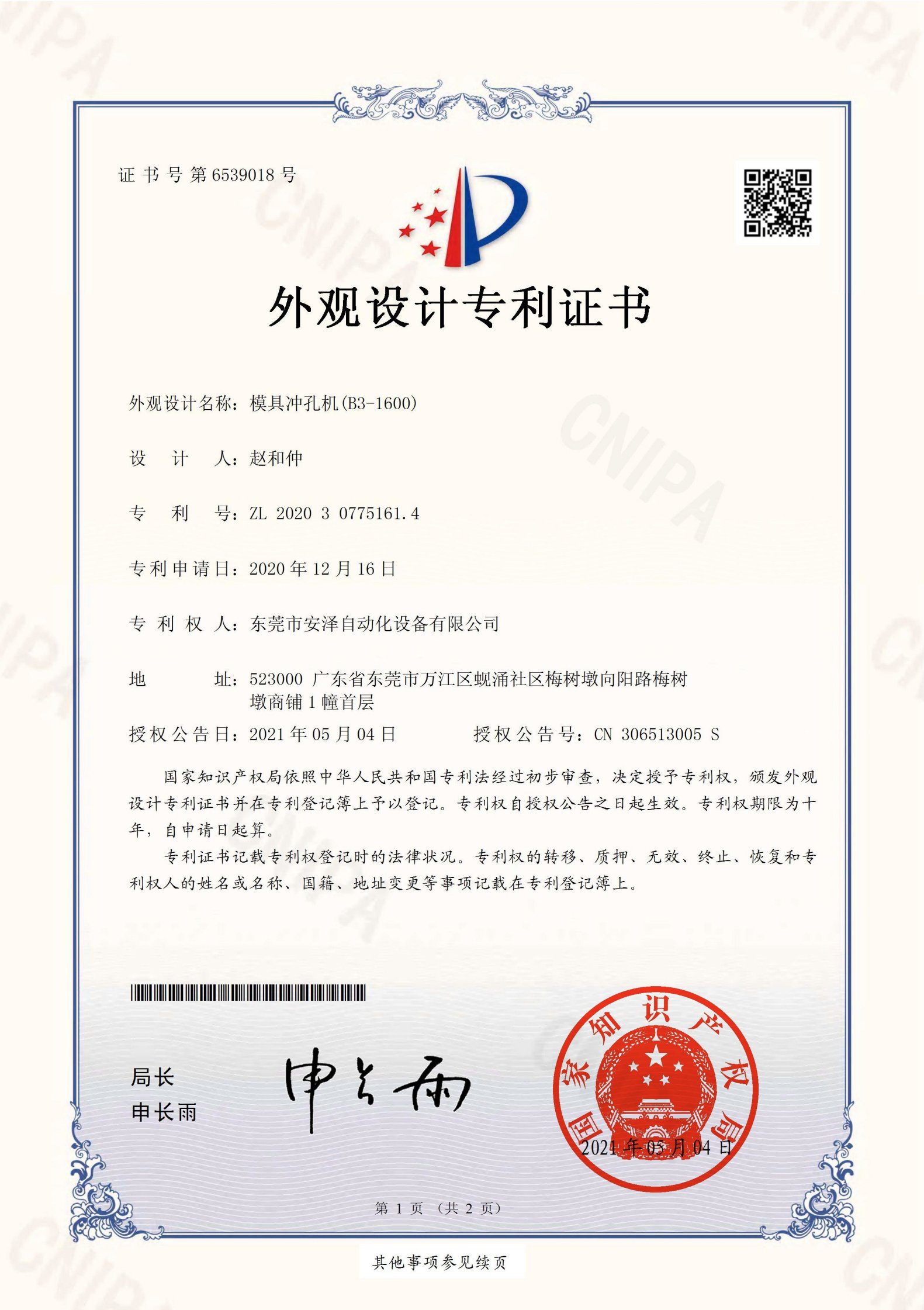

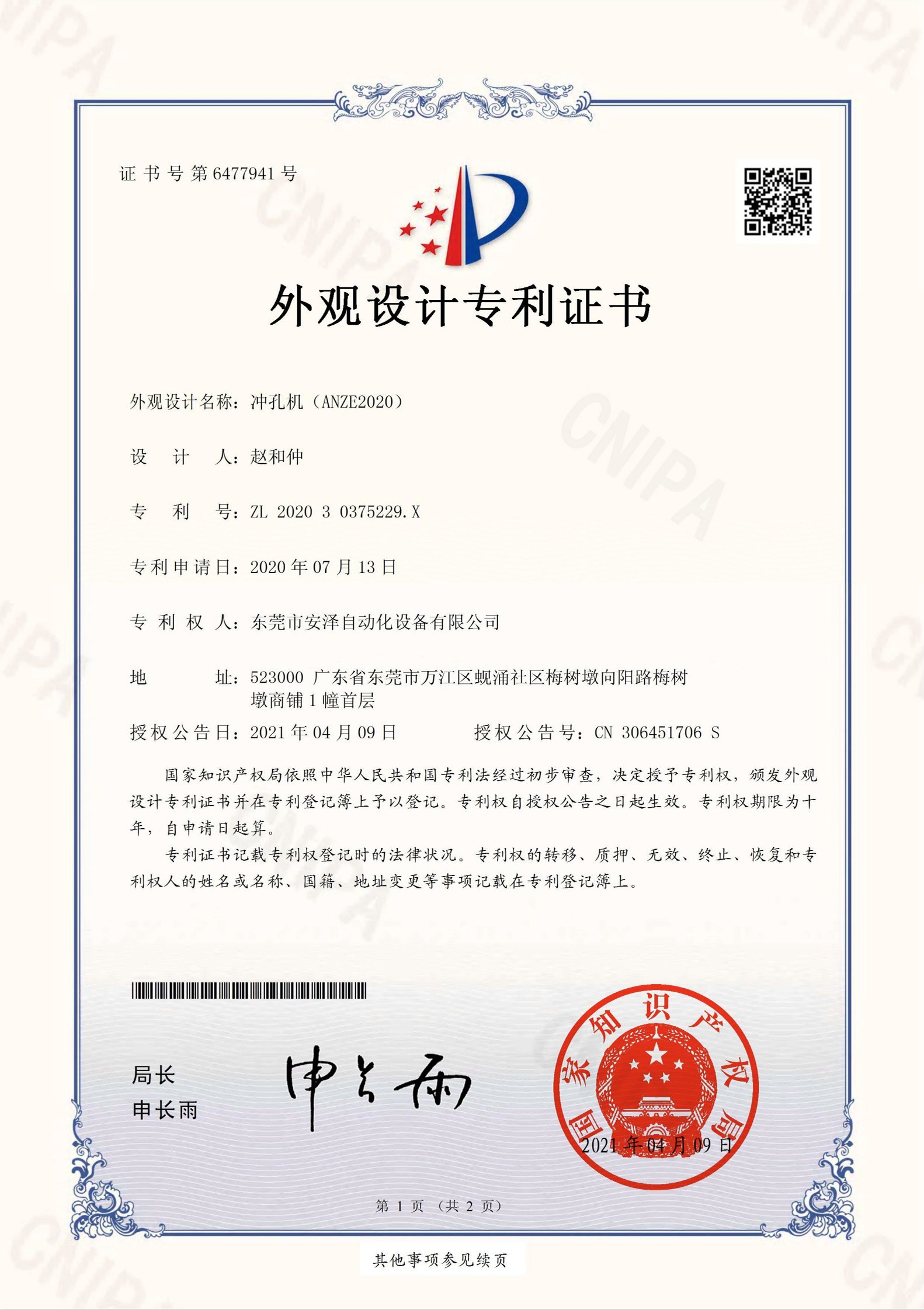

The company has successfully obtained more than 30 national patents, marking an important breakthrough in technological innovation and intellectual property protection.

The successful development of high-speed digital CNC punching machines A2-G and A2-G2, which reach a punching speed of 900 holes per minute, solidified the company's leading position in the industry.

The B2-800 and B2-1600-P mold punches machine were also successfully introduced, further expanding the company's product line.

It was awarded the title of national high-tech Enterprise, marking that the company has been recognized by the state in terms of technological innovation and research and development capabilities.

Launched the mold mobile punching machine B3-800, B3-1600-R, with its unique design and efficient punching capabilities, won the international customer's high recognition and purchase.

The successful development of the B3-1600-LR large roll diameter leather punching machine has consolidated Anze's leading position in the field of leather punching.

The product line of B4-9565 full-plate punching equipment was launched, which improved the product line of the company.

Expanding the scale, a new intelligent factory with an area of 50,000 square meters was added in Wangniudun Town, providing a broader space for the future development of the company.

Developed A3 series of digital punching machine, punching speed reached 1300 holes/min, once again rewrite the domestic digital CNC leather punching machine efficiency of the most history.

Expanding the scale, a new intelligent factory with an area of 50,000 square meters was added in Wangniudun Town, providing a broader space for the future development of the company.

According to the functions of the punching machine, Anze has unified the naming rules, standardized the equipment model, improved the selection needs of the auto cover factory, leather factory, PVC and other coil factories, and provided customers with more accurate and efficient punching equipment and services.

It is committed to becoming a supplier of comprehensive punching solutions for the automotive interior industry, and clearly guided by the Industry 4.0 route, to create intelligent automotive interior production plants, in order to establish the development direction of the company.

Leather Perforating tool Quality first

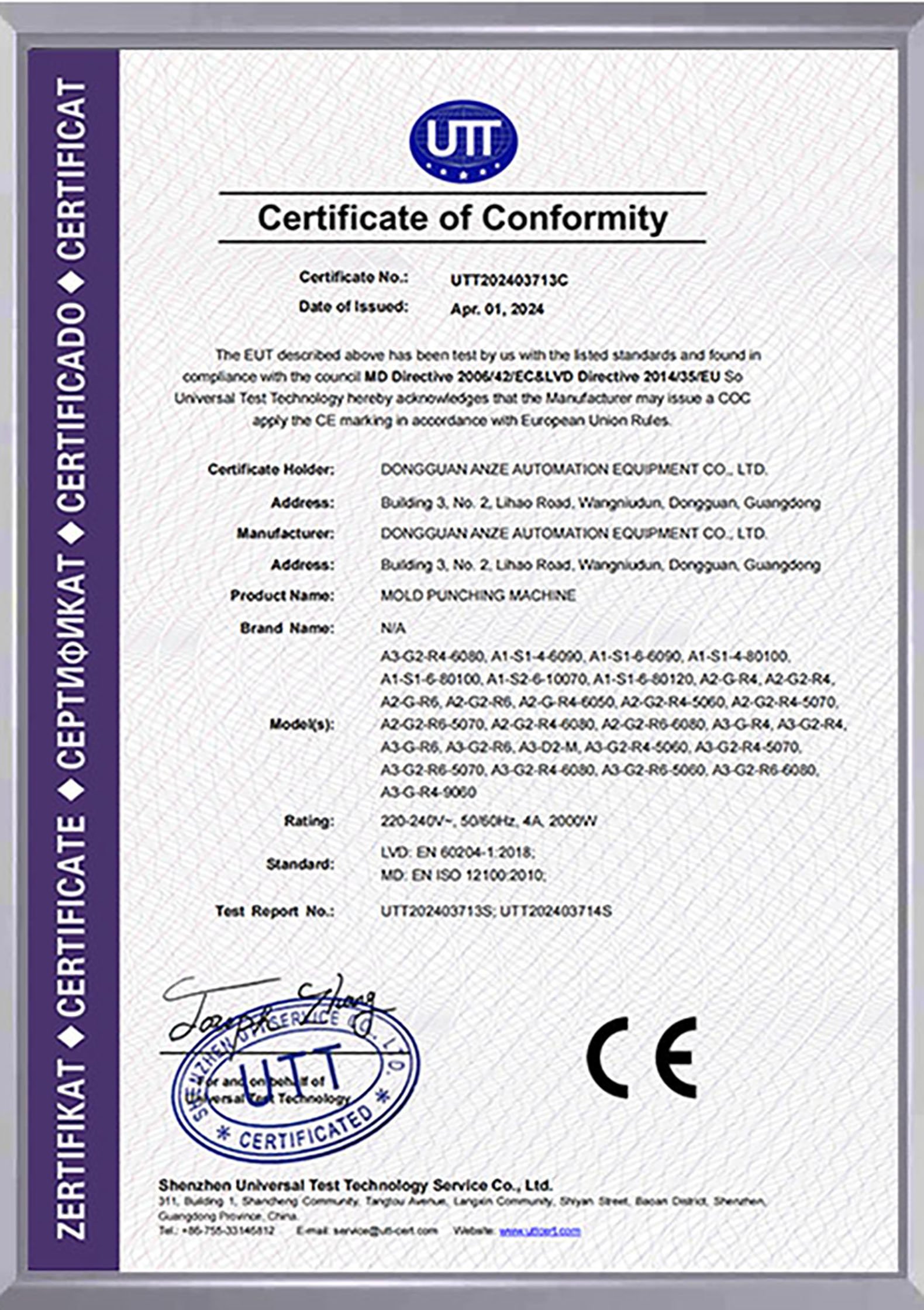

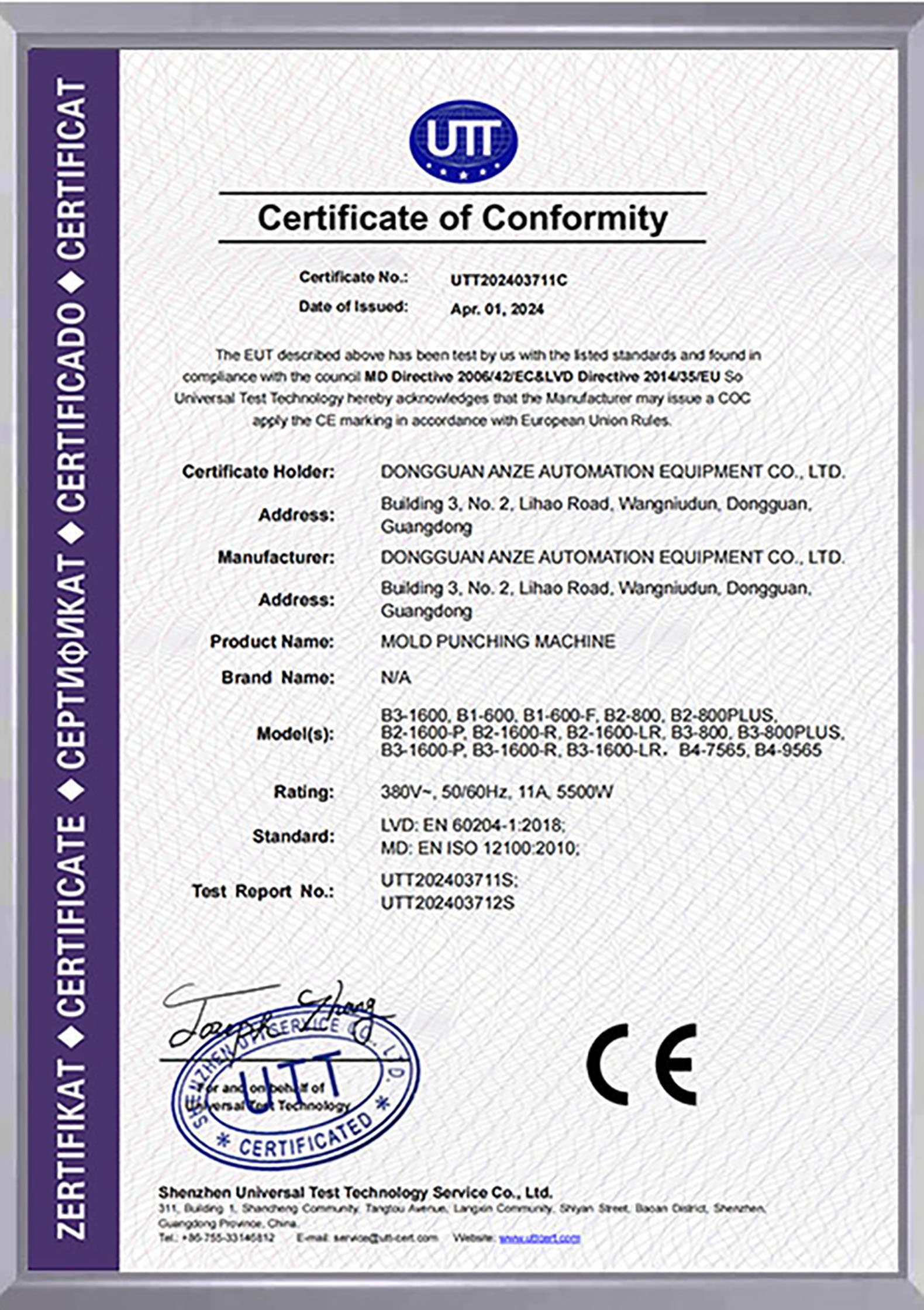

Certifications

In order to provide better product quality and service to meet the needs of customers,our factory and products have passed a lot of inspection and certification, and obtained a lot of certificates.

CNC Leather Perforating tool

With an experienced and skilled team, we are familiar with all kinds of material characteristics and processing technology, and can customize CNC Leather Perforating Machine according to customer needs. Any questions please contact us!

How to install and maintain the machine?

Some models are shipped assembled in the factory. Large equipment is packaged in several parts and an installation manual is provided. All equipment is equipped with user manuals in Chinese and English.

Customers can send someone to anze factory to learn or we send technical experts to provide on-site training

What are the machine working environment requirements?

The CNC Leather Punching Machine should be fixed on a stable table and the environment should be kept clean and tidy to avoid contact with dust, static electricity, humidity, and chips to cause parts failure.

How is your after-sales policies?

We have an experienced after-sales team 24h online service and a completafter-sale system. Factory trainning support, Video technical available to service machinery overseas. support, online support, Engineers.

Are you available for on-the-spot invitation?

Of course we do welcome to visiting our company and have a face-to-face communication to advance mutual business.

What's the delivery time?

Lead time varies depending on the order quantity and customization, typically ranging from 7 to 10 working days.If it is a custom leather punching machine order, it takes 1-2 months.