Last Updated on 2025-07-10 by Anze

As a car seat cover punching machine manufacturer with two decades of experience, we have witnessed the evolution of the automotive industry and the increasing demand for high-quality, customized car seat covers. Our journey as a car seat cover punching machine manufacturer has been marked by innovation, precision, and a commitment to meeting the ever-changing needs of our clients. In this blog, we will delve into the history, processes, and future of our company as a leading car seat cover punching machine manufacturer.

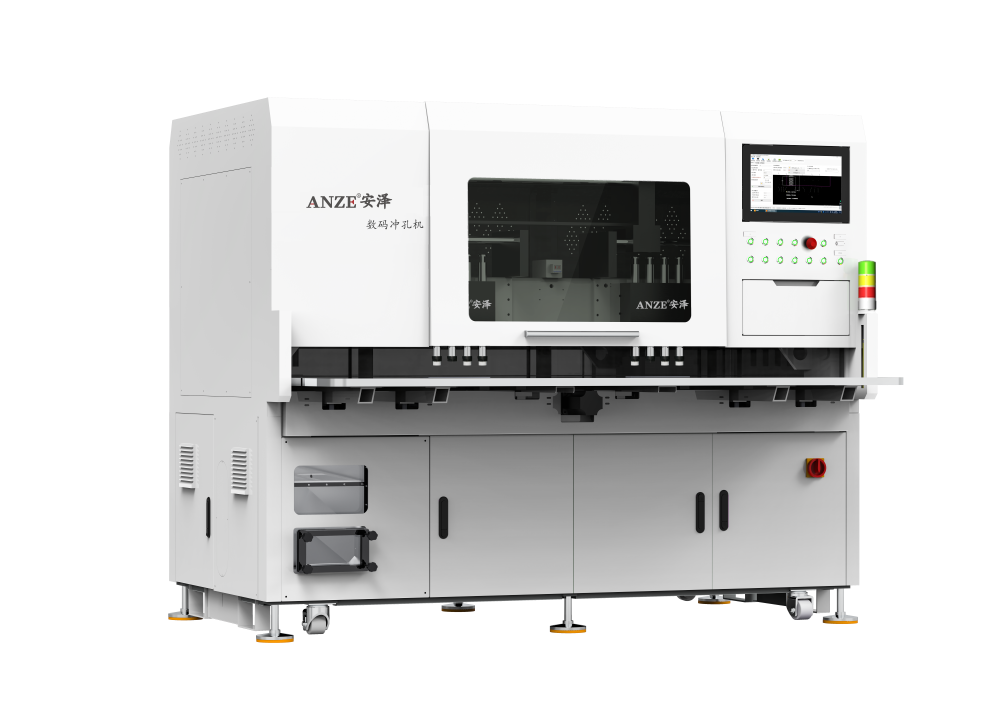

Anze Car Seat Cover Punching Machine Manufacturer

Our story as a car seat cover punching machine manufacturer began over 20 years ago, when our founder, with a vision to revolutionize the automotive interior industry, decided to establish a company dedicated to manufacturing high-quality punching machines. With a focus on innovation and a deep understanding of the market’s needs, we quickly gained a reputation as a reliable and efficient car seat cover punching machine manufacturer.

Early Beginnings and Challenges

In the early days, the automotive industry was still heavily reliant on manual processes, and the concept of automated punching machines for car seat covers was relatively new. As a car seat cover punching machine manufacturer, we faced numerous challenges, including developing machines that could handle the intricate patterns and materials required for car seat covers, while also ensuring precision and efficiency.

Innovation and Growth

Over the years, we have continuously invested in research and development, striving to stay ahead of the curve as a car seat cover punching machine manufacturer. Our dedication to innovation has allowed us to develop machines that not only meet but exceed the expectations of our clients. As the automotive industry evolved, so did our machines, incorporating advanced technologies such as CNC controls, automation, and smart sensors.

From Design to Delivery for Car Seat Cover Punching Machine Manufacturer

As a car seat cover punching machine manufacturer, our process is centered around understanding the unique needs of our clients and delivering customized solutions that meet those needs. From the initial design stage to the final delivery and installation, we take pride in every step of the process.

Understanding Client Needs

The first step in our process as a car seat cover punching machine manufacturer is to understand the specific needs of our clients. We work closely with them to gather information about their production requirements, material specifications, and desired patterns. This allows us to tailor our machines to their exact needs, ensuring optimal performance and satisfaction.

Design and Development

With a clear understanding of our clients’ needs, our team of experienced engineers and designers begins the process of designing and developing the car seat cover punching machine. We utilize state-of-the-art software and technology to create detailed designs and simulations, ensuring that the machine will meet all specifications and perform flawlessly.

Manufacturing and Quality Control

As a car seat cover punching machine manufacturer, we are committed to delivering machines of the highest quality. Our manufacturing process is rigorously controlled, with strict quality checks at every stage. From the selection of materials to the final assembly, we ensure that each component meets our high standards.

Delivery and Installation

Once the car seat cover punching machine is manufactured and passes all quality checks, we arrange for delivery and installation at the client’s facility. Our team of experts handles the installation process, ensuring that the machine is set up correctly and ready for operation. We also provide comprehensive training to the client’s staff, ensuring that they are fully equipped to operate and maintain the machine.

anze Advantages

When it comes to selecting a car seat cover punching machine manufacturer, choosing a specialist with years of experience and a proven track record is crucial. As a leading car seat cover punching machine manufacturer, we offer numerous advantages to our clients, including:

Customized Solutions

As a specialist car seat cover punching machine manufacturer, we understand that every client has unique needs. We offer customized solutions tailored to the specific requirements of each client, ensuring optimal performance and satisfaction.

Advanced Technology

Our commitment to innovation and investment in advanced technology allows us to stay ahead of the curve as a car seat cover punching machine manufacturer. Our machines incorporate the latest technologies, ensuring that our clients benefit from the most efficient and reliable machines on the market.

Quality and Reliability

With over 20 years of experience as a car seat cover punching machine manufacturer, we have established a reputation for quality and reliability. Our machines are built to last, with robust constructions and high-quality components that ensure long-term performance.

Expert Support

Our team of experts is always available to provide support and assistance to our clients. From troubleshooting and maintenance to training and technology consulting, we are dedicated to ensuring that our clients receive the best possible service and support as a car seat cover punching machine manufacturer.

Success Stories from Our Car Seat Cover Punching Machine Manufacturer

Over the years, we have had the privilege of working with numerous clients in the automotive industry, providing them with high-quality car seat cover punching machines. In this section, we will share a few success stories that highlight the impact of our machines and the benefits of choosing a specialist car seat cover punching machine manufacturer.

Case Study 1: A Leading Automotive Manufacturer

One of our most notable clients is a leading automotive manufacturer that required a customized car seat cover punching machine for their production line. After a thorough consultation process, we designed and manufactured a machine that met all their specifications. The result was a significant increase in production efficiency, with reduced labor costs and improved product quality. Our client was extremely satisfied with the performance of the machine and has since become a loyal customer.

Case Study 2: A High-End Car Seat Manufacturer

Another client, a high-end car seat manufacturer, approached us with a unique challenge. They required a car seat cover punching machine that could handle intricate patterns and materials for their luxury car seats. Our team of experts rose to the challenge, designing and manufacturing a machine that exceeded their expectations. The machine’s precision and efficiency allowed our client to produce high-quality car seat covers with consistency, enhancing their reputation in the luxury automotive market.

The Future of Car Seat Cover Punching Machine Manufacturer: Innovation and Sustainability

As a car seat cover punching machine manufacturer with a commitment to innovation and sustainability, we are constantly looking for ways to improve our machines and reduce our environmental impact. In this section, we will discuss the future of our company as a car seat cover punching machine manufacturer and our plans for growth and sustainability.

Investing in Research and Development

Our dedication to innovation and improvement as a car seat cover punching machine manufacturer means that we will continue to invest heavily in research and development. We are constantly exploring new technologies and materials that can enhance the performance and efficiency of our machines. By staying ahead of the curve, we can ensure that our clients benefit from the most advanced and reliable machines on the market.

Sustainability Initiatives

As a responsible car seat cover punching machine manufacturer, we recognize the importance of sustainability and reducing our environmental impact. We are committed to implementing sustainable practices in our manufacturing process, such as reducing waste, conserving energy, and using eco-friendly materials. We also encourage our clients to adopt sustainable practices, promoting the use of recyclable materials and energy-efficient machines.

Expanding Our Global Reach

With the increasing demand for high-quality car seat cover punching machines in the global market, we plan to expand our reach and establish a stronger presence in international markets. By participating in international trade shows and collaborating with partners worldwide, we aim to showcase our machines and expertise to a wider audience.

Customer-Centric Approach

As we grow and evolve as a car seat cover punching machine manufacturer, we will continue to prioritize the needs and satisfaction of our clients. We believe that by understanding their unique requirements and delivering customized solutions, we can build long-lasting relationships and foster mutual success.

Anze-acar seat cover punching machine manufacturer

As a car seat cover punching machine manufacturer with over 20 years of experience, we are proud of our achievements and the trust that our clients have placed in us. Our commitment to innovation, quality, and customer satisfaction has allowed us to become a leading car seat cover punching machine manufacturer in the automotive industry.

With a focus on the future and a dedication to sustainability, we are excited about the opportunities that lie ahead. We will continue to invest in research and development, expand our global reach, and prioritize the needs of our clients. As we move forward, we remain confident that our machines and expertise will continue to make a significant impact in the automotive industry and beyond.

Thank you for choosing us as your trusted car seat cover punching machine manufacturer. We look forward to many more years of innovation, growth, and success together. Any question pls contact May whatsapp +86 180 0298 0031

Some models are shipped assembled in the factory. Large equipment is packaged in several parts and an installation manual is provided. All equipment is equipped with user manuals in Chinese and English.

Customers can send someone to anze factory to learn or we send technical experts to provide on-site training

The machine should be fixed on a stable table and the environment should be kept clean and tidy to avoid contact with dust, static electricity, humidity, and chips to cause parts failure.

We have an experienced after-sales team 24h online service and a completafter-sale system. Factory trainning support, Video technical available to service machinery overseas. support, online support, Engineers.

Of course we do welcome to visiting our company and have a face-to-face communication to advance mutual business.

Lead time varies depending on the order quantity and customization, typically ranging from 7 to 10 working days.If it is a custom leather punching machine order, it takes 1-2 months.