Last Updated on 2025-04-23 by Anze

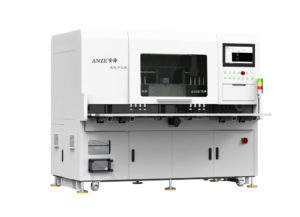

In the world of haute couture and bespoke accessories, the allure of a luxury leather bag lies not just in its material but in the intricate details that define its character. For designers and manufacturers, achieving these details requires tools that blend artistry with engineering precision. As a leading leather perforating machine manufacturer, we take pride in empowering brands to push the boundaries of creativity. Today, we share how our leather perforating machine has become the go-to solution for premium bag producers worldwide—including a renowned French custom bag brand that recently chose our technology to elevate their collections.

1. The Art and Science Behind Our Leather Perforating Machine

A leather perforating machine is more than just industrial equipment; it’s a gateway to transforming raw leather into functional art. Our machines are engineered to pierce leather with unmatched accuracy, creating patterns ranging from classic geometric designs to avant-garde motifs. For bag designers, this capability unlocks endless possibilities:

- Custom Patterns: Floral, geometric, or brand-specific logos—our leather perforating machine adapts to any design file.

- Variable Hole Sizes: From micro-perforations for subtle texture to bold cutouts for structural detailing.

- Material Versatility: Works seamlessly with full-grain, suede, embossed, or exotic leathers.

The French luxury bag brand discovered this versatility firsthand. After reviewing design sketches and sample patterns, they tested our machine’s ability to replicate their intricate floral motifs. The result? Flawless perforations that preserved leather integrity while enhancing visual appeal.

2. Why Premium Bag Brands Trust Our Leather Perforating Machine

From Parisian ateliers to Milanese workshops, top-tier bag manufacturers prioritize precision, speed, and consistency. Here’s how our leather perforating machine meets these demands:

a. Precision Engineering for Flawless Detailing

Our machines employ servo-driven technology and CNC-guided tooling, ensuring every hole aligns perfectly with digital designs. For the French client, this meant achieving uniform depth and spacing across delicate, curved patterns—a feat manual methods couldn’t replicate.

b. Speed Without Compromise

Luxury doesn’t have to mean slow. Our leather perforating machine processes up to 1,500 holes per minute, enabling brands to meet tight deadlines without sacrificing quality.

c. Scalability for Bespoke and Mass Production

Whether crafting limited-edition collections or high-volume orders, our machines switch between designs with minimal downtime. The French brand, known for its made-to-order pieces, appreciated this flexibility to cater to exclusive client requests.

3. A French Luxury Brand’s Journey: From Concept to Collaboration

The partnership with the French custom bag producer exemplifies how our leather perforating machine bridges creativity and technical execution:

Step 1: Digital Design Integration

The brand shared CAD files of their signature floral and lattice patterns. Our team optimized the designs for perforation, adjusting hole density to balance aesthetics and leather durability.

Step 2: Sample Testing and Feedback

Using our leather perforating machine, we produced sample panels on the brand’s preferred leathers. The client praised the machine’s ability to maintain sharp edges on complex shapes—a common challenge with traditional punching tools.

Step 3: On-Site Factory Visit and Order Finalization

Impressed by the samples, the brand’s technical team will visit our factory to observe the machine’s operation firsthand. The agenda includes:

- Live demonstrations of multi-pattern perforation.

- Discussions on integrating the machine into their existing workflow.

- Training sessions for their artisans and engineers.

This visit will culminate in the procurement of two machines, tailored to their studio’s unique needs.

4. Beyond Aesthetics: Functional Benefits of Leather Perforation

While perforations elevate a bag’s design, they also enhance functionality—a critical factor for high-end brands:

- Ventilation: Perforated panels in totes or backpacks improve airflow, ideal for travel or everyday use.

- Weight Reduction: Strategic perforation minimizes material use without compromising strength.

- Texture and Grip: Patterns add tactile appeal, making bags easier to handle.

Our leather perforating machine enables designers to merge form and function seamlessly. For the French brand, this meant creating lightweight yet durable crossbody bags with intricate perforated accents—a collection that quickly became a customer favorite.

5. Sustainable Craftsmanship: Reducing Waste with Precision

Luxury brands are increasingly prioritizing sustainability. Our leather perforating machine supports this shift through:

- Nesting Software: Optimizes leather sheet layouts to minimize scrap.

- Energy-Efficient Operation: Consumes 30% less power than conventional hydraulic systems.

- Longevity: Durable components reduce the need for frequent replacements.

The French client highlighted sustainability as a key motivator for choosing our technology, aligning with their commitment to eco-conscious production.

6. Global Impact: Serving Iconic Bag Manufacturers

Our leather perforating machine has earned the trust of prestigious brands across fashion hubs:

- Italy: A Milan-based brand uses our machines to craft perforated handles for their flagship briefcases.

- Japan: A Kyoto atelier employs our technology for minimalist perforated clutches.

- USA: A New York designer leverages our tools to create avant-garde perforated textures.

These collaborations underscore our machines’ adaptability to diverse design philosophies and market demands.

7. The Future of Bag Design: Smart Leather Perforating Machines

Innovation never stops. We’re pioneering next-gen features to redefine luxury bag production:

- AI-Powered Pattern Recognition: Automatically adjusts perforation depth based on leather thickness.

- IoT Connectivity: Remote monitoring and predictive maintenance alerts.

- 3D Perforation: Layered hole patterns that create depth and shadow effects.

The French brand has already expressed interest in beta-testing these advancements, aiming to launch a “smart perforation” collection next year.

8. Why Choose Us? The Manufacturer Behind the Machine

As a leather perforating machine manufacturer, our commitment extends beyond hardware:

- End-to-End Support: From design optimization to post-purchase training.

- Custom Solutions: Modify machine specs to fit studio layouts or production goals.

- Global Service Network: 24/7 technical assistance across Europe, Asia, and the Americas.

Redefine Your Brand’s Potential with Our Leather Perforating Machine

The journey with our French partner illustrates how the right technology can elevate a brand’s craftsmanship and market appeal. Whether you’re a bespoke atelier or a large-scale manufacturer, our leather perforating machine offers the precision, versatility, and innovation needed to stay ahead in a competitive industry.

Join the ranks of luxury brands transforming leather into art. Contact us today to schedule a factory tour or request a sample test with your designs.

Some models are shipped assembled in the factory. Large equipment is packaged in several parts and an installation manual is provided. All equipment is equipped with user manuals in Chinese and English.

Customers can send someone to anze factory to learn or we send technical experts to provide on-site training

The machine should be fixed on a stable table and the environment should be kept clean and tidy to avoid contact with dust, static electricity, humidity, and chips to cause parts failure.

We have an experienced after-sales team 24h online service and a completafter-sale system. Factory trainning support, Video technical available to service machinery overseas. support, online support, Engineers.

Of course we do welcome to visiting our company and have a face-to-face communication to advance mutual business.

Lead time varies depending on the order quantity and customization, typically ranging from 7 to 10 working days.If it is a custom leather punching machine order, it takes 1-2 months.