Last Updated on 2025-03-01 by Anze

In the realm of craftsmanship, few nations boast a heritage as rich and storied as Italy when it comes to leatherwork. From the tanneries of Tuscany to the artisanal shoemakers of Florence, Italian leather craftsmanship stands as a testament to centuries-old traditions combined with modern innovation. It is within this vibrant industry landscape that our factory, a specialist in manufacturing leather perforating machine, recently received an exciting inquiry from an esteemed Italian leather craftsmanship merchant. This inquiry marked the beginning of a potential partnership that could revolutionize the leather processing industry in Italy and beyond.

The Art of Leather Craftsmanship in Italy

Italy is synonymous with luxury, elegance, and a deep-rooted respect for craftsmanship. Nowhere is this more evident than in the realm of leatherwork. For generations, Italian artisans have perfected the art of transforming raw hides into works of art, whether it’s crafting a sleek leather handbag, a pair of meticulously stitched shoes, or designing automotive interiors that exude sophistication.

The Italian leather industry is not just about producing goods; it’s about preserving a cultural heritage. Each stitch, each cut, and each perforation tells a story, reflecting the skills and passion of the craftsperson behind it. This dedication to excellence has earned Italian leather goods a reputation for quality and style that is recognized worldwide.

The Need for Precision: Enter the Leather Perforating Machine

Despite the traditional roots of Italian leather craftsmanship, the industry is constantly evolving. Modern consumers demand not only beauty and durability but also innovation and customization. This has led to a growing need for advanced machinery that can meet the precise requirements of contemporary leather processing.

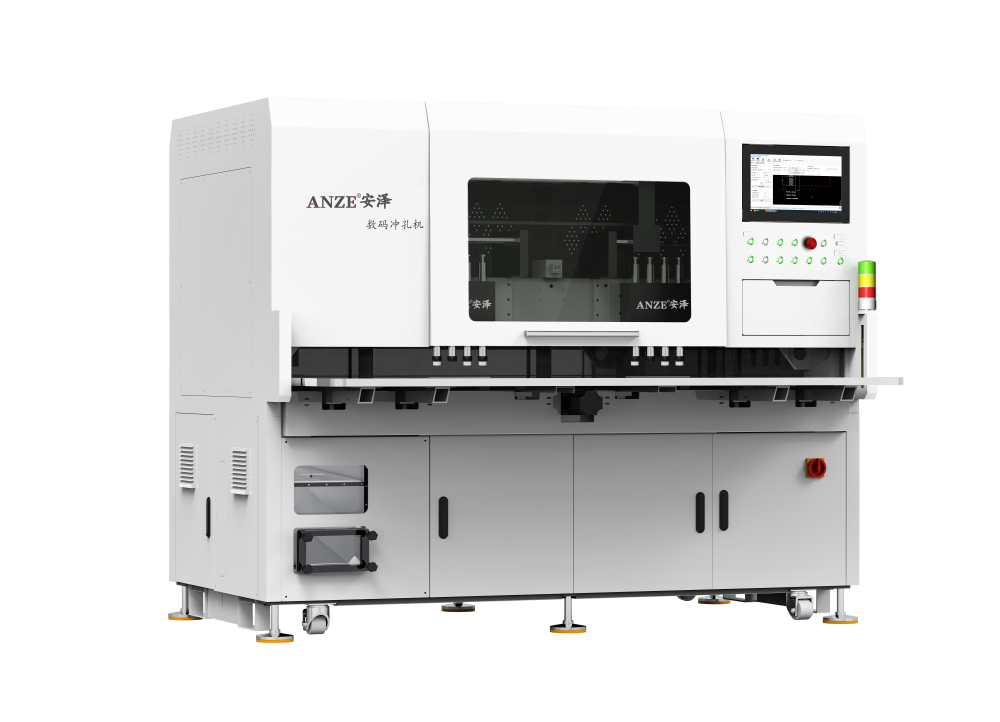

Enter our factory, a leading manufacturer of leather perforating machines. Our machines are designed to deliver unparalleled precision, efficiency, and versatility in leather perforating tasks. Whether it’s creating intricate patterns for fashion accessories, enhancing breathability in automotive seats, or achieving a unique aesthetic for furniture upholstery, our leather perforating machines are engineered to excel.

The Inquiry: A Bridge Between Traditions and Innovations for leather perforating machine

It was through our comprehensive online presence that an Italian leather craftsmanship merchant first discovered us. Impressed by the precision and versatility demonstrated by our leather perforating machines, they reached out with the intention of exploring a potential partnership.

The inquiry came at an opportune moment. Our factory had been looking to expand its international footprint, particularly in regions where leather craftsmanship is deeply ingrained in cultural identity. Italy, with its rich leather heritage and demand for high-quality, customized leather products, seemed like a perfect fit.

The Journey to leather perforating machine Partnership

Initial discussions were promising. The Italian merchant shared their vision for incorporating advanced leather perforating technology into their traditional craftsmanship processes. They envisioned a future where the precision of machinery complemented the skill of human artisans, creating leather goods that were not only beautiful but also technologically advanced.

Our team, excited by the prospect of working with such a revered name in the leather industry, began presenting our range of leather perforating machines. We highlighted features such as:

- High Precision: Our machines utilize state-of-the-art technology to ensure every perforation is perfectly placed, maintaining the integrity of the leather while achieving intricate designs.

- Versatility: Whether it’s creating uniform holes for ventilation or intricate patterns for aesthetic appeal, our machines can adapt to various leather types and thicknesses.

- Efficiency: Automation means faster production times without compromising on quality, helping meet the demands of a competitive market.

- Customization: The ability to create bespoke perforation patterns tailored to specific client needs, enhancing the personalization aspect of leather goods.

Bridging Cultural and Technical Gaps

As discussions progressed, it became clear that the partnership was not just about selling machines; it was about fostering a collaborative relationship. Our factory offered to provide training sessions for the Italian merchant’s team, ensuring they were proficient in operating and maintaining the leather perforating machines. This would not only optimize machine performance but also preserve the unique skills of the artisans involved.

Furthermore, we proposed a joint research and development initiative. By combining our technical expertise with the merchant’s deep understanding of leather craftsmanship, we aimed to develop new perforation techniques and designs that could push the boundaries of what was possible.

The Future of Leather Craftsmanship in Italy

The potential partnership between our factory and the Italian leather craftsmanship merchant holds immense promise for the future of the industry. It represents a fusion of traditional craftsmanship with cutting-edge technology, creating a synergy that could redefine leather processing.

For the Italian merchant, access to our advanced leather perforating machines means being able to offer clients customized, high-quality leather goods with unparalleled precision and efficiency. This, in turn, could open up new markets and solidify their position as a leader in the luxury leather goods sector.

For our factory, the partnership represents an opportunity to gain insights into the nuances of Italian leather craftsmanship, further refining our machines to better meet the needs of artisans worldwide. It also presents a platform for us to showcase our technology to a broader audience, potentially leading to more collaborations and expansion into new territories.

A Partnership Rooted in Craftsmanship and leather perforating machine

In the end, the inquiry from the Italian leather craftsmanship merchant served as a reminder of the enduring power of craftsmanship combined with technological innovation. By partnering with us, they are not just acquiring machines; they are embarking on a journey to preserve and elevate their craft, ensuring it remains relevant and admired for generations to come.

As we move forward, we are excited about the possibilities that lie ahead. The leather perforating machine is not just a tool; it’s a bridge connecting the past with the future, tradition with innovation, and artisanship with technology. Together, we stand at the cusp of a new era in leather craftsmanship, ready to create masterpieces that celebrate the beauty of leather in all its forms.

Our factory looks forward to a fruitful partnership with the Italian merchant, one that will undoubtedly leave an indelible mark on the leather industry, solidifying our role as pioneers in leather perforating technology. Stay tuned for updates as we embark on this exciting journey together.

Some models are shipped assembled in the factory. Large equipment is packaged in several parts and an installation manual is provided. All equipment is equipped with user manuals in Chinese and English.

Customers can send someone to anze factory to learn or we send technical experts to provide on-site training

The machine should be fixed on a stable table and the environment should be kept clean and tidy to avoid contact with dust, static electricity, humidity, and chips to cause parts failure.

We have an experienced after-sales team 24h online service and a completafter-sale system. Factory trainning support, Video technical available to service machinery overseas. support, online support, Engineers.

Of course we do welcome to visiting our company and have a face-to-face communication to advance mutual business.

Lead time varies depending on the order quantity and customization, typically ranging from 7 to 10 working days.If it is a custom leather punching machine order, it takes 1-2 months.