Last Updated on 2025-02-25 by Anze

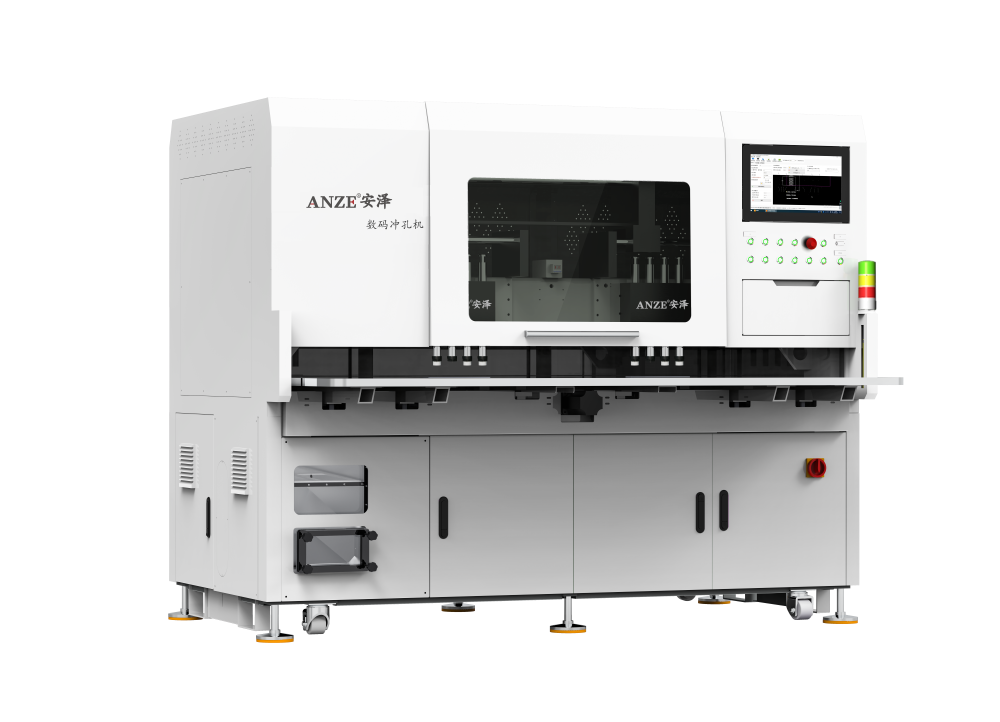

In the rapidly developing automotive industry, the refinement and comfort of interior decoration have become one of the important criteria for measuring the quality of automobiles. As a professional leather punching machine manufacturer, ANZE has always been at the forefront of technological innovation and is committed to providing efficient and precise leather processing solutions for the global automotive manufacturing industry. On this occasion, we are honored to announce that ANZE will bring its latest developed car seat cover leather punching machine to the upcoming CIMP International Auto Parts Exhibition. This is not only a display of our technical strength, but also a profound insight and response to the future development trend of the automotive industry.

1. ANZE: The leader of leather punching technology

Since its establishment, ANZE has focused on the research and development and application of leather punching technology with the core concept of “technological innovation and excellent quality”. Our product line covers various types of leather punching machines from basic to high-end intelligent, which are widely used in automotive interiors, furniture, luggage, shoes and other fields. With deep technical accumulation, strict quality control and flexible customized services, ANZE has won the trust and praise of many customers at home and abroad, and has become a force that cannot be ignored in the industry.

2. Car seat cover leather punching machine: innovation leads the future

The latest car seat cover leather punching machine exhibited by ANZE is a masterpiece that integrates years of technical accumulation and innovative thinking to meet the customized needs of the automotive interior industry. This model not only achieves a qualitative leap in performance, but also reflects the precise grasp of the future trend of personalized and intelligent automotive interiors in design concept.

High-precision intelligent positioning

Adopting advanced laser navigation system combined with precision servo motor drive, ANZE’s new leather punching machine can achieve micron-level positioning accuracy, ensuring that each hole can be accurately placed in the preset position, whether it is a complex pattern or a fine texture, it can be perfectly presented, meeting the extremely high requirements of car seat covers for accuracy.

High-efficiency punching technology

Combined with high-speed rotating punches and optimized punching path algorithms, this machine greatly improves work efficiency while ensuring punching quality. Compared with traditional equipment, the time for processing the same area of leather can be shortened by more than 30%, effectively reducing production costs and improving the market competitiveness of enterprises.

Diversified mold design

For leathers of different materials, thicknesses and design requirements, ANZE provides a wealth of mold options, from standard round and square to complex geometric patterns, and can even customize special shape molds according to customer requirements. This flexibility ensures the diversity of seat cover punching styles and meets the market’s growing demand for personalized customization.

Environmental protection and energy saving, green production

In response to the global call for environmental protection, ANZE’s new leather punching machine fully considers energy efficiency and material utilization when designing. It uses low-energy motors and intelligent energy-saving control systems to reduce energy consumption; at the same time, the optimized waste recycling system minimizes material waste and helps companies achieve green production.

Intelligent human-computer interaction interface

Equipped with an intuitive and easy-to-use touch screen operating system, users can easily set punching parameters, preview design effects, and monitor processing progress. In addition, the machine also supports remote monitoring and fault diagnosis functions, which facilitates remote support by technicians to ensure the continuous and stable operation of the production line.

3. The story behind leather punching machine technological innovation

The birth of ANZE’s new car seat cover leather punching machine is the result of countless experiments and optimizations by the team. From market research to demand analysis, from concept design to prototype manufacturing, every step embodies the wisdom and sweat of ANZE engineers. We are well aware that in this ever-changing era, only by continuous innovation can we remain invincible in the fierce market competition.

During the research and development process, the ANZE team went deep into the front line of automotive interior production and worked closely with many well-known automakers to gain a deep understanding of the actual needs and challenges of seat cover production. Through repeated testing and adjustments, we successfully overcame the problems of positioning deviation and low efficiency that traditional punching machines are prone to when processing complex patterns, and finally launched this revolutionary product that combines efficiency, precision and flexibility.

4. Exhibition Outlook: Building a New Future for Automotive Interiors

The upcoming International Auto Parts Exhibition is a grand event for the global automotive industry, bringing together top companies and innovative technologies from all over the world. ANZE Company exhibited its new leather punching machine for automotive seat covers, aiming to discuss the development trend of automotive interior technology with colleagues in the industry and share our innovative achievements. At the same time, we also look forward to establishing cooperative relationships with more potential customers to jointly promote the transformation and upgrading of the automotive interior industry.

During the exhibition, the ANZE team will demonstrate the operation process and actual application effect of the new leather punching machine on site, allowing visitors to experience its excellent performance firsthand. We will also hold a technical exchange meeting to invite industry experts and participants to discuss the latest progress and application prospects of leather punching technology, and contribute to the innovative development of the automotive interior industry.

V. ANZE Commitment: Continuous Innovation, Service First

ANZE is well aware that every technological innovation is the fulfillment of its commitment to customers. We not only provide advanced products, but also pay more attention to the improvement of the after-sales service system. Whether it is pre-sales consultation, installation and commissioning, or after-sales maintenance and technical support, ANZE will be customer-oriented and provide a full range of personalized service solutions to ensure that every customer can enjoy the best service experience.

Looking to the future, ANZE will continue to uphold the core values of “technological innovation, quality excellence”, constantly explore the boundaries of leather punching technology, and bring more subversive solutions to the automotive industry. We believe that through continuous efforts and innovation, ANZE will work hand in hand with global partners to jointly create a more brilliant future for the automotive interior industry.

the new car seat cover leather punching machine

At the upcoming International Auto Parts Exhibition, ANZE sincerely invites friends from all walks of life to visit our booth to witness the elegance of the new car seat cover leather punching machine. Let us go hand in hand and write a more wonderful chapter together on the road of innovation in automotive interior technology!

ANZE, with technology as its wings and quality as its foundation, looks forward to creating a better future with you!

Thanks for reading, and I hope this article has given you some valuable insights into the world of leather punching machines. If you have any questions or would like to share your own experiences, feel free to leave a comment below.If you want to watch video of leather punching machine,please visit our YOUTUBE CHANEL https://www.youtube.com/@Anze-Perforation-machine

Some models are shipped assembled in the factory. Large equipment is packaged in several parts and an installation manual is provided. All equipment is equipped with user manuals in Chinese and English.

Customers can send someone to anze factory to learn or we send technical experts to provide on-site training

The machine should be fixed on a stable table and the environment should be kept clean and tidy to avoid contact with dust, static electricity, humidity, and chips to cause parts failure.

We have an experienced after-sales team 24h online service and a completafter-sale system. Factory trainning support, Video technical available to service machinery overseas. support, online support, Engineers.

Of course we do welcome to visiting our company and have a face-to-face communication to advance mutual business.

Lead time varies depending on the order quantity and customization, typically ranging from 7 to 10 working days.If it is a custom leather punching machine order, it takes 1-2 months.