Last Updated on 2025-02-20 by Anze

In the automotive manufacturing industry, seats are not only the main components for passengers to rest and ride, but also an important element to show the style and quality of vehicle interiors. As consumers’ requirements for the beauty and comfort of automotive interiors are increasing, the design and manufacture of automotive seats are also facing higher challenges. Among them, leather punching solutions technology, as a process that can not only improve the beauty of seats but also enhance their breathability and comfort, has gradually occupied an important position in the manufacture of automotive seats. This article will explore in depth the solutions for leather punching of automotive seats, including the basic principles of punching technology, design considerations, implementation steps, quality control and future development trends.

1. Basic principles of leather punching technology

Leather punching technology is a process that forms regular or irregular hole patterns on the surface of leather by mechanical or laser methods. These holes can not only increase the breathability of leather and improve the comfort of seats, but also show the individuality and fashion sense of vehicles through different pattern designs. The basic principles of punching technology can be summarized as follows:

1.1 Mold design:

Design and manufacture special punching molds according to the shape, size and required hole pattern of the seat. The precision and durability of the mold directly affect the quality of punching.

1.2 Punching operation:

Place the leather material on the punching machine and punch the leather through the up and down movement of the mold. The punching force, speed and frequency need to be controlled during the punching process to ensure that the size, shape and arrangement of the holes meet the expectations.

1.3 Subsequent processing:

After the punching is completed, the leather needs to be trimmed, deburred and other subsequent processing to improve the flatness and aesthetics of the leather.

2. Considerations for leather punching design

When designing leather punching for car seats, multiple factors need to be considered comprehensively to ensure that the punching pattern meets both aesthetic requirements and functional requirements of the seat.

Seat type and use: Different types of car seats (such as driver’s seat, co-pilot seat, rear seat, etc.) have different requirements for leather punching. For example, the driver’s seat and co-pilot seat may require more dense punching to increase breathability, while the rear seat may pay more attention to aesthetics.

Passenger comfort: The design of the punching pattern should take into account the comfort of the passengers. The size, shape and arrangement of the holes should be able to effectively disperse the pressure on the seat surface and reduce discomfort during long-term riding.

Vehicle interior style: The leather punching pattern should be coordinated with the overall style of the vehicle interior. For example, luxury models may prefer to use delicate and exquisite punching patterns to show their high-end quality; while sports models may use a more rugged and dynamic punching design.

Material characteristics: Leather of different materials has different requirements for punching technology. For example, some leathers may be more prone to burrs or tears, so more delicate operations and subsequent treatments are required during the punching process.

3. Implementation steps of leather punching

The implementation steps of leather punching for car seats usually include the following links:

3.1 Material preparation:

Select leather materials suitable for punching, and perform necessary pretreatment (such as cleaning, drying, etc.) to ensure the quality of punching.

3.2 Mold preparation:

Manufacture or adjust the punching mold according to design requirements to ensure the accuracy and durability of the mold.

3.3 Punching operation:

Place the leather material on the punching machine and use the mold for punching. During the punching process, it is necessary to pay close attention to the punching quality and adjust the punching parameters in time to ensure that the size, shape and arrangement of the holes meet expectations.

3.4 Subsequent processing:

The leather after punching is trimmed, deburred and other subsequent processing is carried out to improve the flatness and beauty of the leather.

3.5 Quality inspection:

The leather after punching is quality inspected to ensure that the punching quality meets the design requirements. If necessary, repair or rework is required.

4. Quality control of leather punching

In order to ensure the quality of leather punching in car seats, a series of quality control measures need to be taken. These measures include:

Mold quality control: Regularly inspect and maintain the punching mold to ensure the accuracy and durability of the mold. If the mold is found to be worn or damaged, it should be repaired or replaced in time.

Punching process monitoring: Pay close attention to the punching quality during the punching process, and adjust the punching parameters in time to ensure that the size, shape and arrangement of the holes meet the expectations. If the punching quality is unstable or abnormal, the machine should be stopped immediately for inspection and troubleshooting.

Subsequent processing inspection: When trimming and deburring the leather after punching, the processing effect should be carefully checked to ensure the flatness and beauty of the leather.

Quality inspection standards: Establish clear quality inspection standards and conduct strict quality inspection on the leather after punching. The inspection content includes the size, shape, arrangement of the holes, and the flatness and aesthetics of the leather.

Recording and tracing: Establish a punching quality record system to record the quality of each batch of punched leather in detail. If quality problems are found, they should be traced back and the root cause of the problem should be found in time.

5. Future development trend of leather punching technology

With the continuous development of the automobile manufacturing industry and the changing needs of consumers, the punching technology of automobile seat leather will also show new development trends. These trends include:

Personalized customization: With the increase in consumers’ demand for personalization, automobile seat leather punching technology will pay more attention to personalized customization services. By introducing advanced digital design and manufacturing technologies, consumers can customize unique punching patterns and seat styles according to their preferences and needs.

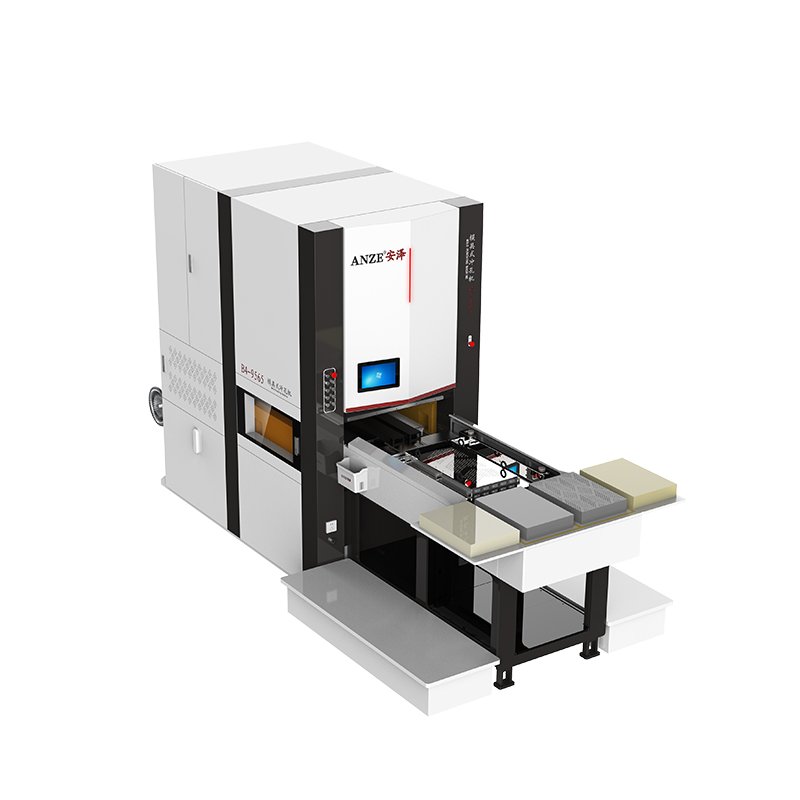

Intelligent production: With the continuous development of intelligent manufacturing technology, automobile seat leather punching technology will gradually realize intelligent production. By introducing advanced equipment and technical means such as intelligent robots and automated production lines, production efficiency and product quality can be improved while reducing production costs.

Environmental protection and sustainable development: With the continuous improvement of environmental awareness and the popularization of the concept of sustainable development, the automotive seat leather punching technology will also pay more attention to environmental protection and sustainable development. By adopting environmentally friendly materials, energy-saving and emission-reducing production processes and other means to reduce the impact on the environment and achieve green production.

Multifunctional design: In the future, the automotive seat leather punching technology will not only be limited to increasing breathability and aesthetics, but will also develop in a multifunctional direction. For example, by integrating heating, ventilation, massage and other functions to improve the comfort and health of the seat; or by introducing intelligent sensors and control systems to achieve automatic adjustment and intelligent control of the seat.

6.improve the aesthetics and comfort of seats

As an important means to improve the aesthetics and comfort of seats, automobile seat leather punching technology plays an increasingly important role in the automotive manufacturing industry. By deeply understanding the basic principles, design considerations, implementation steps and quality control measures of punching technology, we can better master this technology and apply it to actual production. At the same time, with the development of trends such as personalized customization, intelligent production, environmental protection and sustainable development, and multifunctional design, automobile seat leather punching technology will also usher in a broader development prospect.

If you want to watch video of leather punching machine,please visit our YOUTUBE CHANEL https://www.youtube.com/@Anze-Perforation-machine

Some models are shipped assembled in the factory. Large equipment is packaged in several parts and an installation manual is provided. All equipment is equipped with user manuals in Chinese and English.

Customers can send someone to anze factory to learn or we send technical experts to provide on-site training

The machine should be fixed on a stable table and the environment should be kept clean and tidy to avoid contact with dust, static electricity, humidity, and chips to cause parts failure.

We have an experienced after-sales team 24h online service and a completafter-sale system. Factory trainning support, Video technical available to service machinery overseas. support, online support, Engineers.

Of course we do welcome to visiting our company and have a face-to-face communication to advance mutual business.

Lead time varies depending on the order quantity and customization, typically ranging from 7 to 10 working days.If it is a custom leather punching machine order, it takes 1-2 months.