Last Updated on 2025-02-20 by Anze

In the vast field of manufacturing, the processing of flexible materials has always been a perfect combination of technology and art. With the advancement of science and technology, the punching technology of flexible materials is also constantly innovating, especially in leather, a classic and charming material. The application of punching technology not only improves the aesthetics of the product, but also achieves new breakthroughs in functionality. This article will explore in depth the punching machine solutions of flexible materials, especially leather, and analyze the current technical status, challenges and future development trends.

1. Background and significance of leather punching machine and technology

Leather, as a flexible material with a long history and wide application, occupies an important position in many fields such as fashion, furniture, and automotive interiors due to its unique texture, durability and beauty. However, traditional leather processing methods are often limited to basic processes such as cutting and sewing, which are difficult to meet the growing personalized and diversified needs. The introduction of punching technology has brought revolutionary changes to leather processing.

Punching technology can not only create rich and diverse patterns and textures, enhance the artistic value of leather products, but also adjust the breathability and elasticity of leather by changing the distribution and size of holes to meet the functional needs in specific scenarios. For example, the application of punching technology on car seats can not only enhance the comfort and breathability of the seats, but also enhance the luxury of the interior through fine pattern design.

2. The current status and challenges of leather punching machine

2.1 Current status

At present, leather punching technology has made significant progress. Automated and intelligent punching equipment continues to emerge, making the punching process more efficient and precise. These devices usually use CNC technology, which can automatically complete the leather punching operation according to preset patterns and parameters. At the same time, with the advancement of materials science, the emergence of new leather materials also provides a broader application space for punching technology.

2.2 Challenges

Although leather punching technology has made great progress, it still faces some challenges. First, as a flexible material, leather is prone to deformation and tearing during the punching process, which puts higher requirements on the accuracy and stability of the equipment. Secondly, different types of leather differ in thickness, toughness, etc., requiring punching equipment to have high adaptability and flexibility. In addition, with the increasing demand of consumers for personalization and customization, punching technology also needs to continue to innovate in pattern design, color matching, etc.

3. Solutions for leather punching machine technology

In response to the above challenges, the industry has explored a series of solutions to improve the accuracy, efficiency and adaptability of leather punching technology.

3.1 High-precision punching equipment

High-precision punching equipment is the key to improving the quality of leather punching. Such equipment usually adopts advanced CNC systems and precise mechanical structures to achieve micron-level punching accuracy. At the same time, the equipment is also equipped with a variety of punch shapes and sizes to adapt to different types and thicknesses of leather materials. In addition, some high-end equipment also has automatic calibration and compensation functions, which can monitor and adjust the punching position in real time to ensure the accuracy and consistency of the pattern.

3.2 Flexible mold technology

Flexible mold technology is an innovative solution that uses flexible materials (such as silicone, rubber, etc.) to make molds to adapt to different types and shapes of leather materials. This mold has good adaptability and durability, and can maintain a stable shape and size during the punching process. At the same time, flexible molds are easy to replace and maintain, reducing production costs and cycles.

3.3 Intelligent control system

Intelligent control system is an important means to improve the efficiency and adaptability of leather punching. Such systems usually integrate advanced technologies such as image recognition and artificial intelligence, and can automatically identify information such as the type, thickness and texture of leather, and automatically adjust the working state of the punching equipment according to the preset patterns and parameters. In addition, the intelligent control system also has remote monitoring and fault diagnosis functions, which can monitor the operating status of the equipment in real time and detect potential problems in time.

3.4 Personalized customization service

With the increasing demand of consumers for personalization and customization, leather punching technology also needs to continue to innovate to meet market demand. Personalized customization service is an effective solution. By providing a variety of options such as pattern design, color matching and material selection, consumers can customize unique leather products according to their preferences and needs. At the same time, companies can also use big data and artificial intelligence technology to analyze consumer preferences and behavior patterns to provide more accurate and personalized services.

4. Application cases of leather punching technology

Leather punching technology has been widely used in many fields, bringing unique visual effects and functional improvements to products. The following are some typical application cases:

4.1 Fashion accessories

In the field of fashion accessories, leather punching technology is widely used in handbags, wallets, belts and other products. Through fine pattern design and clever color matching, punching technology adds unique fashion elements and personalized style to these products. At the same time, the punching process also improves the breathability and comfort of the product, making consumers more pleasant during use.

4.2 Automotive interior

In the field of automotive interior, leather punching technology is widely used in products such as seats, steering wheels, and door panels. Through punching, these products not only enhance the luxury and sportiness of the interior, but also enhance the breathability and comfort of the seats. In addition, punching technology also helps to reduce the weight of the interior and reduce the noise level, improving the driving experience and riding comfort of the whole vehicle.

4.3 Furniture decoration

In the field of furniture decoration, leather punching technology is widely used in products such as sofas, chairs, and bedside tables. Through fine pattern design and clever punching, these products not only enhance the artistic atmosphere and personalized style of the home environment, but also enhance the comfort and durability of the furniture. At the same time, punching technology also helps to reduce the weight and space occupied by furniture, and improve the overall beauty and practicality of the home environment.

5.Future Outlook for leather punching machine

With the advancement of science and technology and the changing needs of consumers, leather punching technology will continue to develop towards higher precision, higher efficiency and higher adaptability. In the future, we can expect the following trends:

Technology integration and innovation: With the continuous development of technologies such as the Internet of Things, big data, and artificial intelligence, leather punching technology will achieve deep integration and innovative application with these technologies. For example, through intelligent sensors and data analysis technology, real-time monitoring of key parameters and indicators in the leather punching process can improve production efficiency and product quality.

Environmental protection and sustainable development: With the continuous improvement of environmental awareness and the popularization of the concept of sustainable development, leather punching technology will also pay more attention to environmental protection and sustainable development. For example, the use of environmentally friendly materials and energy-saving technologies can reduce energy consumption and emissions in the production process; and recycling and remanufacturing technologies can be used to reduce resource waste and environmental pollution.

Personalized and customized services: With the increasing demand for personalization and customization by consumers, leather punching technology will pay more attention to providing personalized and customized services. For example, through online design platforms and 3D printing technology, consumers can independently design and customize unique leather products; through big data analysis and artificial intelligence technology, more accurate and personalized product recommendations and services can be provided.

As an important technology in the field of flexible material processing, leather punching technology is constantly promoting the innovation and development of related industries. With the continuous advancement of technology and the continuous expansion of application fields, we have reason to believe that the future leather punching technology will be more intelligent, efficient and personalized, bringing consumers a more high-quality, unique and environmentally friendly product experience.

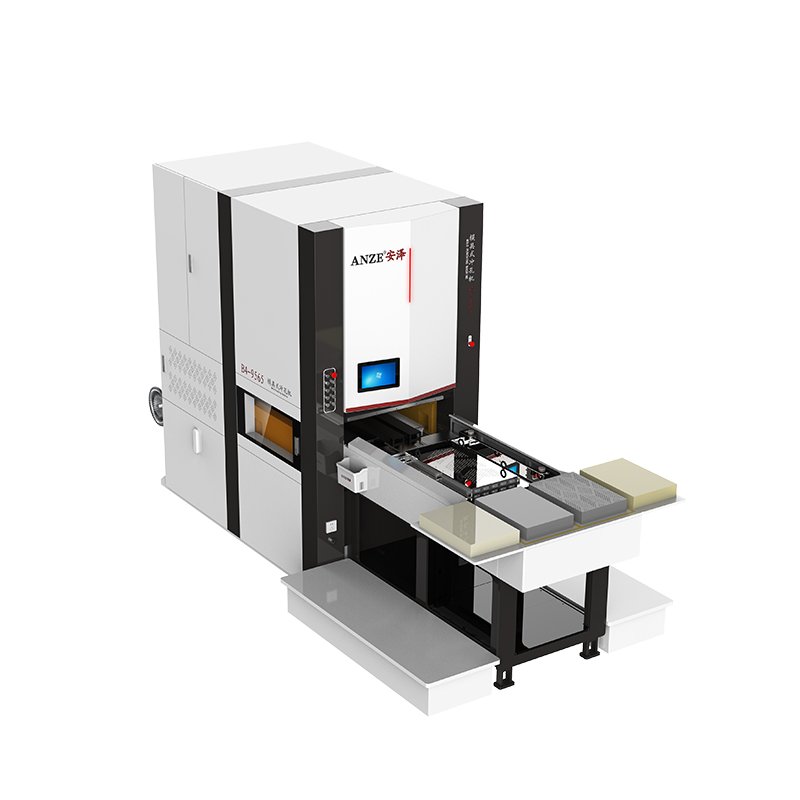

Anze leather punching machine

Since 2005, Anze focus on the development and manufacture of leather punching machine. We are committed to providing our customers with better leather punching solutions,hole punching machine for leather!

For all soft and semi-rigid materials, leather, foam, textiles and miscellaneous non-textile complex materials, in sheets or rolls, we offer perforation* and punching** on:

- perforating and punching machines, in widths of 3 to 1600mm

- punch-die or drill press systems, both sequential and rotating.

All our designs follow the same cycle: Prototype-Validation / Pre-Production-Validation / Production.

**perforation: the material is cut out and removed

** punching: a hole is made in the material using a needle, or a raised shape is created with a motif

Can’t find your motif amongst our range? Our design office is on hand to design and create the best solution for you.

If you want to watch video of leather punching machine,please visit our YOUTUBE CHANEL https://www.youtube.com/@Anze-Perforation-machine

Some models are shipped assembled in the factory. Large equipment is packaged in several parts and an installation manual is provided. All equipment is equipped with user manuals in Chinese and English.

Customers can send someone to anze factory to learn or we send technical experts to provide on-site training

The machine should be fixed on a stable table and the environment should be kept clean and tidy to avoid contact with dust, static electricity, humidity, and chips to cause parts failure.

We have an experienced after-sales team 24h online service and a completafter-sale system. Factory trainning support, Video technical available to service machinery overseas. support, online support, Engineers.

Of course we do welcome to visiting our company and have a face-to-face communication to advance mutual business.

Lead time varies depending on the order quantity and customization, typically ranging from 7 to 10 working days.If it is a custom leather punching machine order, it takes 1-2 months.