Last Updated on 2025-02-20 by Anze

In the leather processing industry, leather perforating machine is key equipment for improving production efficiency and ensuring product quality. Their selection is crucial for manufacturers. This article will explore in depth how to choose a leather punching machine manufacturer and recommend several top leather punching machine manufacturers to help you make a more informed decision.

How to choose a leather perforating machine manufacturer

1. Understand market demand and your own needs

Before choosing a leather perforating machine manufacturer, you first need to clarify your own production needs and market needs. This includes understanding the type of leather products you plan to produce (such as shoes, bags, furniture, etc.), production scale (small batch customization or large-scale production), budget constraints, and special requirements for equipment performance (such as accuracy, speed, stability, etc.). Clarifying these needs will help narrow the range of choices and ensure that the selected equipment can meet your actual needs.

2. Research the reputation and strength of the manufacturer

When choosing a leather perforating machine manufacturer, it is crucial to understand its reputation and strength. You can obtain relevant information through the following channels:

Online search and word-of-mouth inquiry: Use search engines and social media platforms to query the manufacturer’s customer reviews, industry reputation, and user feedback. This information can provide you with an intuitive reference to help you judge the reputation and service quality of the manufacturer.

Visit the factory and field investigation: If conditions permit, visit the manufacturer’s factory in person to understand its production environment, equipment status, technical strength and after-sales service system. This will help you have a more comprehensive understanding of the manufacturer’s strength and potential.

Check industry reports and certifications: Check relevant industry reports, market analysis reports and the manufacturer’s qualification certification. This information can provide you with a more objective and comprehensive reference.

3. Pay attention to equipment performance and technical parameters

When choosing a leather perforating machine, the performance and technical parameters of the equipment are important indicators to measure its quality. You need to pay attention to the following aspects:

Precision and stability: Make sure that the selected equipment has high processing accuracy and stability, and can meet your strict requirements for the quality of leather products.

Speed and efficiency: Understand the processing speed and efficiency of the equipment to ensure that it can meet your production needs and reduce production costs.

Adaptability and flexibility: Choose a punching machine that can adapt to different leather materials, thicknesses and shapes to improve the versatility and flexibility of the equipment.

Energy consumption and environmental protection: Pay attention to the energy consumption and environmental performance of the equipment, and choose a low-energy, low-emission punching machine to meet the sustainable development concept of modern enterprises.

4. Consider after-sales service and technical support

Good after-sales service and technical support are important guarantees for long-term and stable operation of the equipment. When choosing a leather punching machine manufacturer, you need to pay attention to the following aspects:

Warranty policy and period: Understand the warranty policy, warranty period and maintenance service process provided by the manufacturer. This will help you get repairs and support in time when the equipment fails.

Technical training and support: Choose a manufacturer that provides comprehensive technical training and support to ensure that your employees can master the operation and maintenance skills of the equipment.

Spare parts supply and upgrade service: Understand whether the manufacturer provides spare parts supply and upgrade services to ensure that the equipment can continue to receive support and updates during long-term operation.

top leather perforating machine manufacturers recommendations

1.TESEO:

their story begins among the green hills of Marche Region, in the largest footwear manufacturing area in Europe, where Gianni Gallucci lives. In 1987, Gallucci graduated with full marks with a thesis about a software project named TESEO. In the same year – in the garage of his house-, he created TESEO and, upon requests of friends and artisans who worked in the footwear sector, the IDEA is born.

2.Wista:

The Wista Group was founded in Bad Rappenau by Gerd Staudinger and Karl-Heinz Wimmer back in 1991. Today we are among the world leaders for technically sophisticated solutions in the area of perforation systems. Our product portfolio also includes toolmaking for the construction of modern production systems that adhere to the highest quality standards.

Products manufactured using Wista technology are found in a wide variety of applications and industries. They include: Automotive, textiles, hygiene, medicine, stamps, sound insulation, building services, outside advertising and many more.

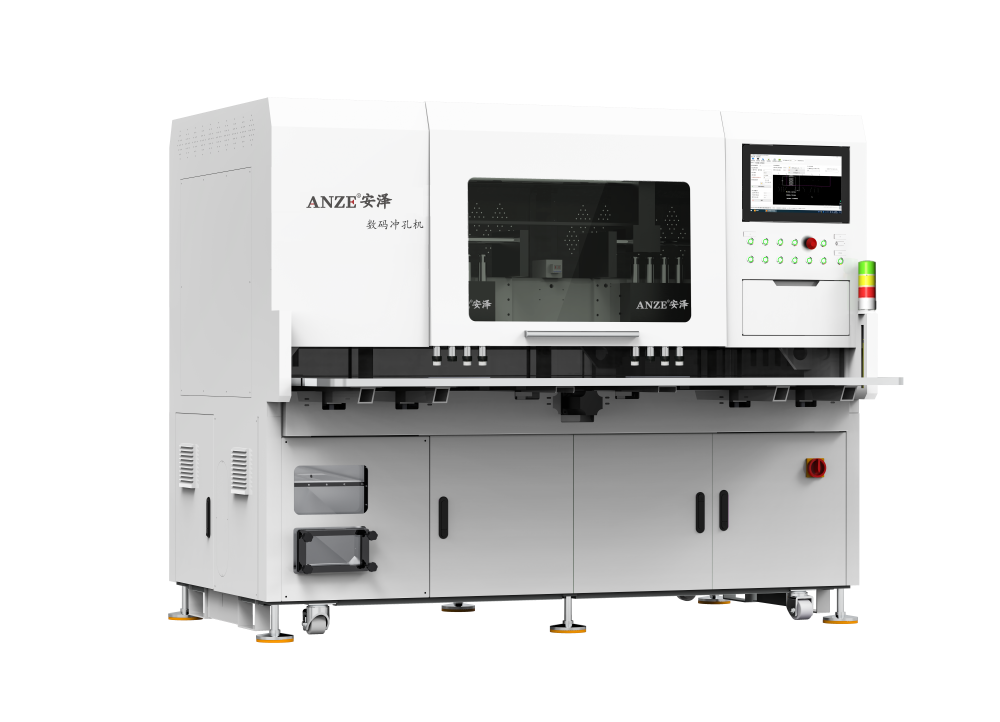

3.Anze

Dongguan Anze Automation Equipment Co., Ltd. is located in Dongguan City,Guangdong Province. Founded in 2005, the company has been focusing on the punching industry for nearly 20 years and currently covers a comprehensive area of 5000 squaremeters. The company specializes in CNC leather perforating machines, mould leather punching machines,leather bag punching machine,luggage leather punching machine,shoes leather punching machine,furniture leather punching machine and other equipment.

4.Ring

The Ring Group has specialised in perforating for more than 100 years. They manufacture leather perforating machine as well as punching, shoemaking and tanning machines, special machines, devices and tools to customer specifications. Decades of experience and continuous development enable us to pass on the highest technical standards in perforating to you. Whether machines, tools, design development, contract perforation or service in all areas – “You get everything from a single source, completely made in Germany!” We are at your disposal worldwide and perforate or emboss worldwide at our locations on a contract basis, i.e. your material is perforated or embossed in the desired pattern.

5.Gersone

Gersone is the one of top Die cutting machine Factory in China, our die cutting machine factory is located in yancheng, Jiangsu Province. 100,000 square meters of production workshop. More than 100 senior engineers. More than 1,000 skilled workers.35 years experience let Gersone possess the same premier quality as the original machines made in the Europe.

How ahout Anze leather perforating machine

Anze targets customer needs and focuses on product development, developing total of 25 products in the A and B series.

We are the company which have mature and comprehensive intelligent punching solution for materials in automotive interiors.

We have become strategic partners with over 600 leather product manufacturers. including 36 exporting countries.

If you want to watch video of leather punching machine,please visit our YOUTUBE CHANEL https://www.youtube.com/@Anze-Perforation-machine

Some models are shipped assembled in the factory. Large equipment is packaged in several parts and an installation manual is provided. All equipment is equipped with user manuals in Chinese and English.

Customers can send someone to anze factory to learn or we send technical experts to provide on-site training

The machine should be fixed on a stable table and the environment should be kept clean and tidy to avoid contact with dust, static electricity, humidity, and chips to cause parts failure.

We have an experienced after-sales team 24h online service and a completafter-sale system. Factory trainning support, Video technical available to service machinery overseas. support, online support, Engineers.

Of course we do welcome to visiting our company and have a face-to-face communication to advance mutual business.

Lead time varies depending on the order quantity and customization, typically ranging from 7 to 10 working days.If it is a custom leather punching machine order, it takes 1-2 months.