Last Updated on 2025-05-25 by Anze

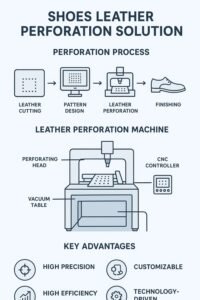

In the vast world of fashion and industrial design, leather, as a classic and timeless material, always occupies a pivotal position. From luxury handbags to exquisite shoes, from vintage furniture to modern car interiors, leather has become the first choice of many designers and manufacturers with its unique texture, durability and beauty. Behind this, leather perforation machine, as an important tool for leather processing, are quietly changing the production methods and creative boundaries of leather products. This article will explore the various uses of leather perforation machines in depth and reveal how they bring unlimited possibilities to the design and manufacture of leather products.

1. leather perforation machine Personalized customization: meeting diverse needs

As consumers’ demand for personalized products grows, leather perforation machine have become a key tool to meet this demand. By precisely controlling the location, shape, and size of the punching holes, manufacturers can provide consumers with unique customized services. Whether it is engraving a personal name, a special date, or creating a unique pattern and texture, the leather punching machine can easily achieve it, making each leather product a unique work of art that carries personal emotions and stories.

2. Enhance the aesthetics of design: create a unique visual effect

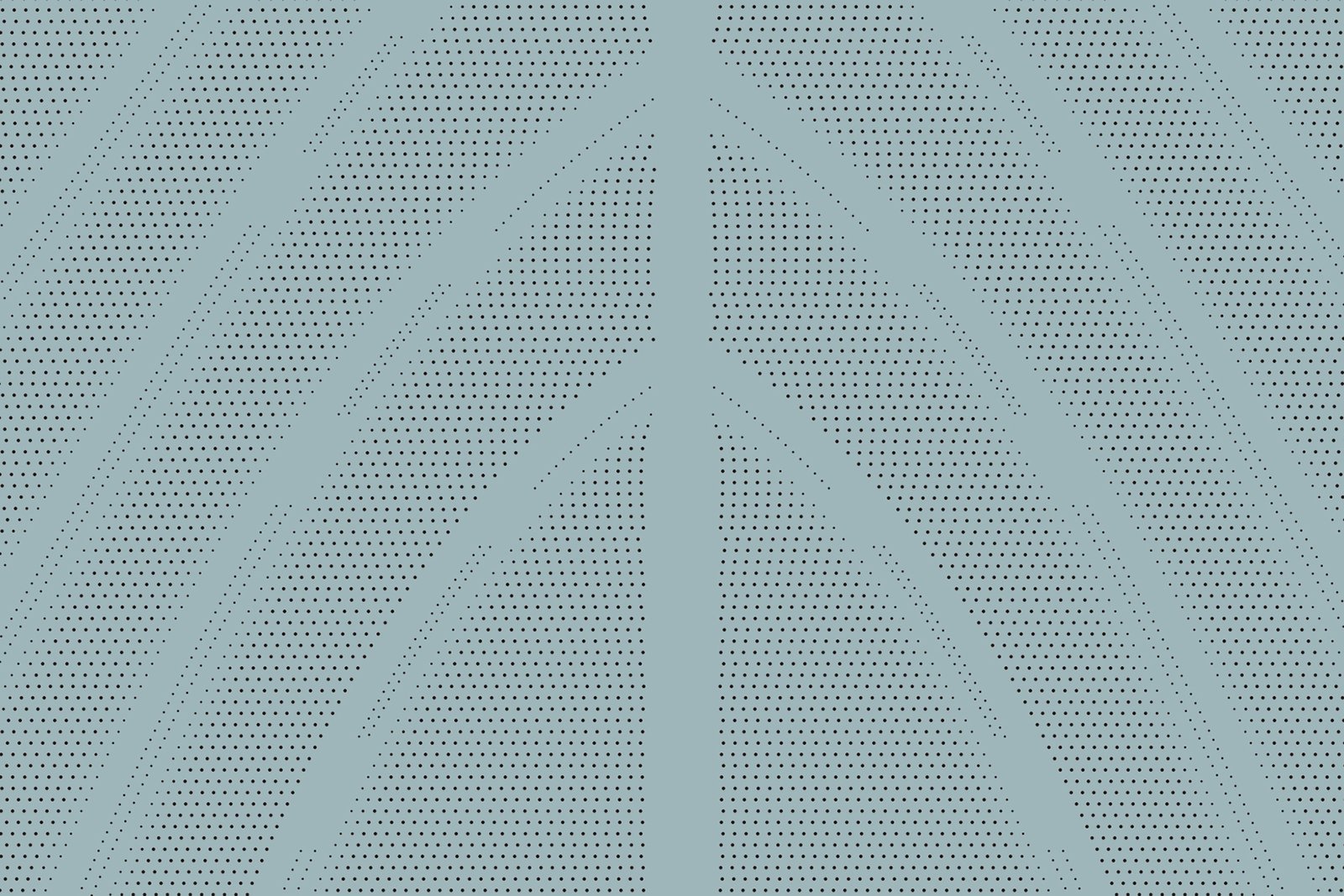

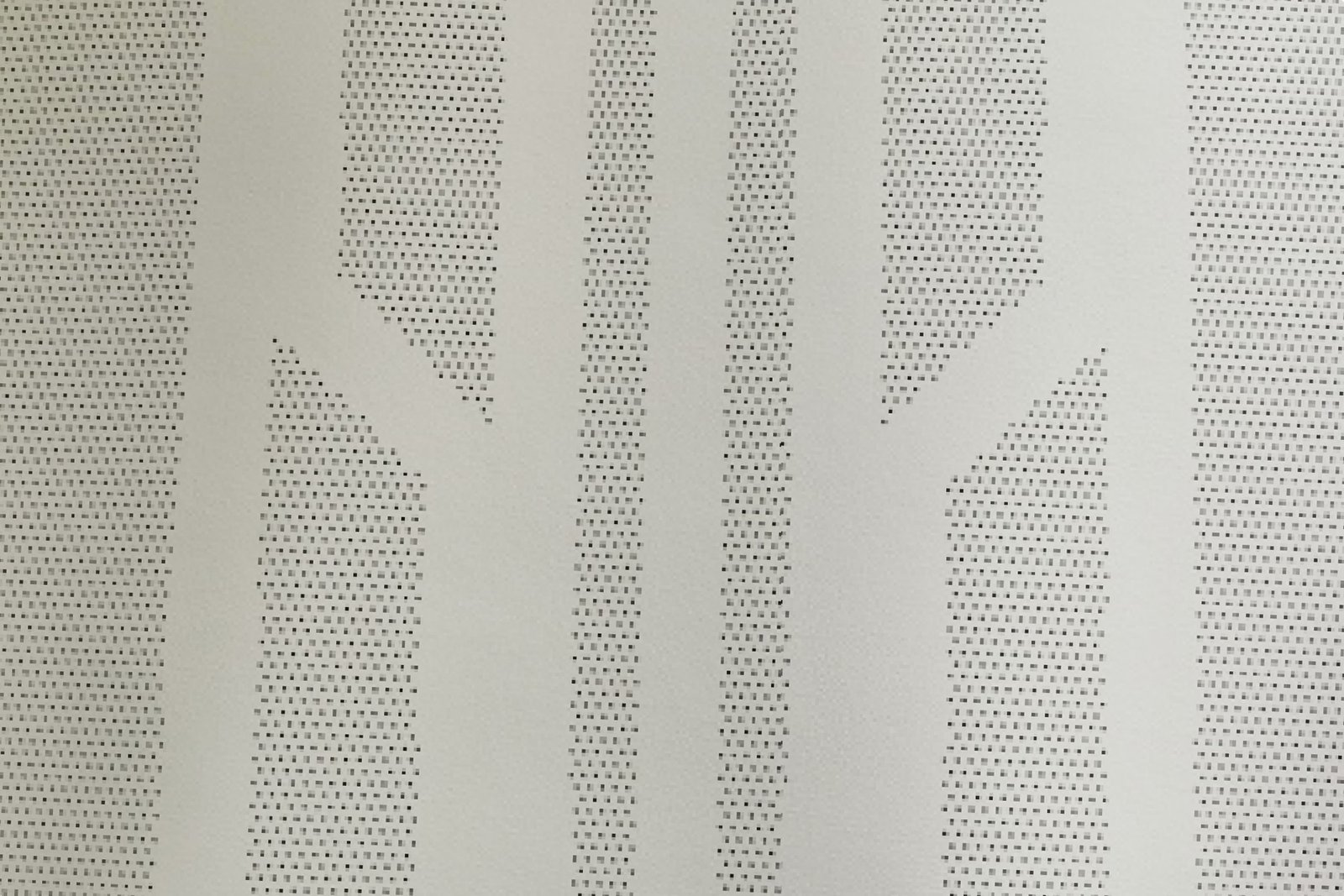

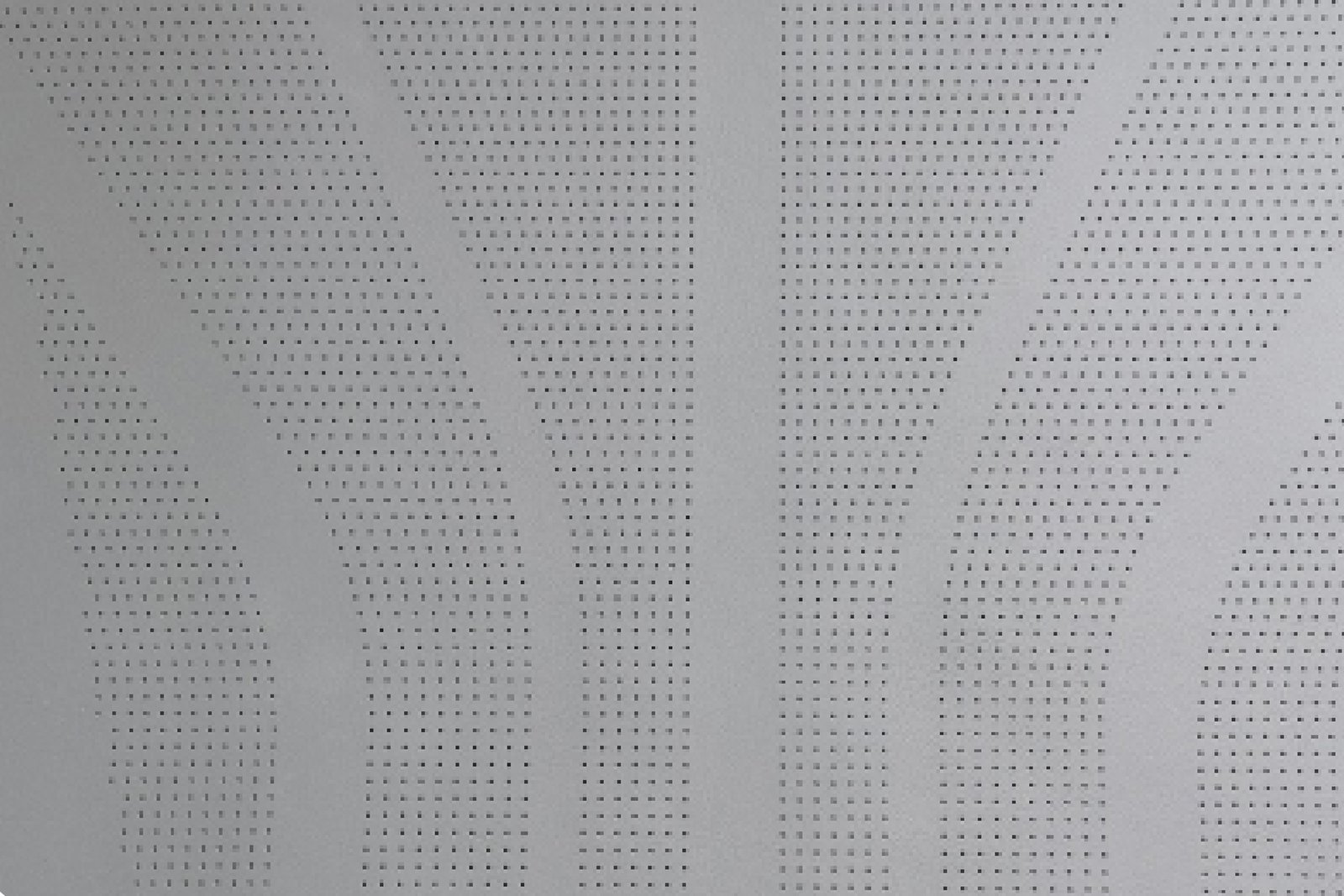

Leather punching machine can not only achieve basic punching functions, but also add a unique visual aesthetic to leather products through carefully designed punching patterns. Whether it is a delicate dot pattern, a streamlined line, or a complex geometric figure, the punching machine can accurately present it, giving the leather product a sense of layering and three-dimensionality. This design not only enhances the overall beauty of the product, but also makes it stand out from many similar products and attract the attention of consumers.

3. Improve breathability and comfort: Improve user experience

Leather perforation machines also play an important role in leather products such as shoes and seats that need to consider breathability and comfort. By properly distributing the punching holes, the air permeability of the leather surface can be effectively increased, the air circulation can be improved, and the user’s feeling of stuffiness can be reduced, thereby improving the comfort of wearing or using. This design is particularly suitable for products that need to contact the skin for a long time, such as sports shoes and car seats, and can effectively improve the user experience.

4. leather perforation machine Assist industrial production

For leather product manufacturers, leather perforation machines are not only a tool to improve product design and comfort, but also the key to improving production efficiency and reducing costs. Compared with the traditional manual punching method, leather punching machines can achieve automation and batch production, greatly improving production speed and quality stability. At the same time, because the punching process is more precise and efficient, it can also effectively reduce material waste and labor costs, bringing significant economic benefits to manufacturers.

5. leather perforation machine Promote innovation in leather products

With the advancement of technology and consumers’ continuous pursuit of innovative products, leather perforation machine is playing an increasingly important role in promoting innovation in leather products. By combining with other advanced technologies, such as 3D printing and laser cutting, leather punching machines can create more complex and sophisticated punching patterns and structures, bringing unprecedented possibilities to the design and production of leather products. These innovations not only enrich the types and styles of leather products, but also meet consumers’ desire for novel and unique products.

Anze Focus on R&D of leather perforation machine

With the advancement of technology and consumers’ continuous pursuit of innovative products, leather perforation machine is playing an increasingly important role in promoting innovation in leather products. By combining with other advanced technologies, such as 3D printing and laser cutting, leather punching machines can create more complex and sophisticated punching patterns and structures, bringing unprecedented possibilities to the design and production of leather products. These innovations not only enrich the types and styles of leather products, but also meet consumers’ desire for novel and unique products. Any question please contact May whatsapp

Some models are shipped assembled in the factory. Large equipment is packaged in several parts and an installation manual is provided. All equipment is equipped with user manuals in Chinese and English.

Customers can send someone to anze factory to learn or we send technical experts to provide on-site training

The machine should be fixed on a stable table and the environment should be kept clean and tidy to avoid contact with dust, static electricity, humidity, and chips to cause parts failure.

We have an experienced after-sales team 24h online service and a completafter-sale system. Factory trainning support, Video technical available to service machinery overseas. support, online support, Engineers.

Of course we do welcome to visiting our company and have a face-to-face communication to advance mutual business.

Lead time varies depending on the order quantity and customization, typically ranging from 7 to 10 working days.If it is a custom leather punching machine order, it takes 1-2 months.