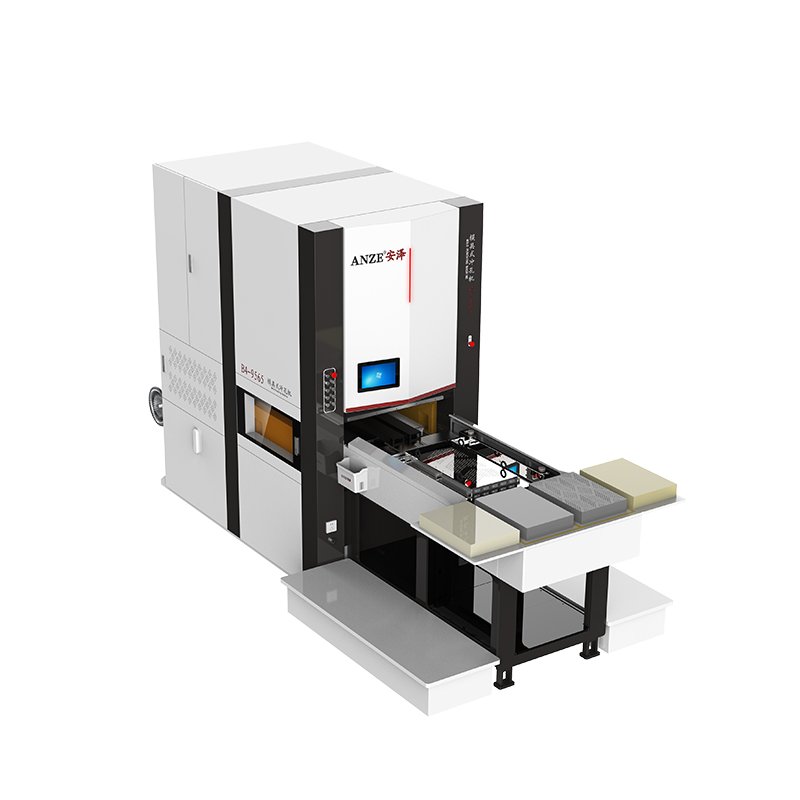

Mould Leather Punching Machine B4-7565

B4-7565 is one of B4 series mould leather punching machine ,which is used for mass production of both regular perforation and personalized perforation of materials either in rolls or in pieces

B4 Series Mould Leather Punching Machine

B4-7565 Parameters

B4-7565 Mould Leather Punching Machine

Profile & features

Mould leather punching machine B4-7565 is used for mass production of both regular perforation and personalized perforation of materials either in rolls (PVC, microfiber, artificial leather, etc.), or in pieces (genuine leather) for automotive upholstery industry.

The machine has high punching efficiency and stable performance, and is easy to operate. The machine is suitable for leather factories, leather traders,car seat cover factories, and dedicated punching workshops.

- 1.The whole version of the mould, the pattern is determined by the mould

- 2.It can press 21000 round holes with a diameter of 1.0mm at one time

- 3.Special transportation platform is responsible for the entry and exit of leather, which can ensure people and personal safety

- 4.The mould has a service life of 300,000 times

- 5.The depth of the mould can be adjusted automatically, and the fully automatic adjustment of the life cycle of the punching needle

- 6.The mould with leather positioning funciton

- 7.The machine is equipped with paper rack and leather rack, the scene is clean and refreshing

- 8.The new noise technology developed can ensure that the noise lower than 75dB

B4-7565 Mould Leather Punching Machine

Punched samples

In order to punch special patterns on the leather, usually we will make some punching samples, and then constantly adjust the leather punching equipment, so that the equipment to achieve the most perfect state. These punching samples are made by B4-7565 Mould Leather Punching Machine.

- Clear pattern lines

- Smooth holes, no burrs

- Suitable for large-scale mass production

- Automatic changing leather punch machine knife

inquiry

Mould Leather Punching Machine Faqs

With an experienced and skilled team, we are familiar with all kinds of material characteristics and processing technology, and can customize Mould Leather Punching Machine according to customer needs. Any questions please contact us!

Some models are shipped assembled in the factory. Large equipment is packaged in several parts and an installation manual is provided. All equipment is equipped with user manuals in Chinese and English.

Customers can send someone to anze factory to learn or we send technical experts to provide on-site training

The CNC Leather Punching Machine should be fixed on a stable table and the environment should be kept clean and tidy to avoid contact with dust, static electricity, humidity, and chips to cause parts failure.

We have an experienced after-sales team 24h online service and a completafter-sale system. Factory trainning support, Video technical available to service machinery overseas. support, online support, Engineers.

Of course we do welcome to visiting our company and have a face-to-face communication to advance mutual business.

Lead time varies depending on the order quantity and customization, typically ranging from 7 to 10 working days.If it is a custom leather punching machine order, it takes 1-2 months.