APPLICATIONS

experience to be trusted

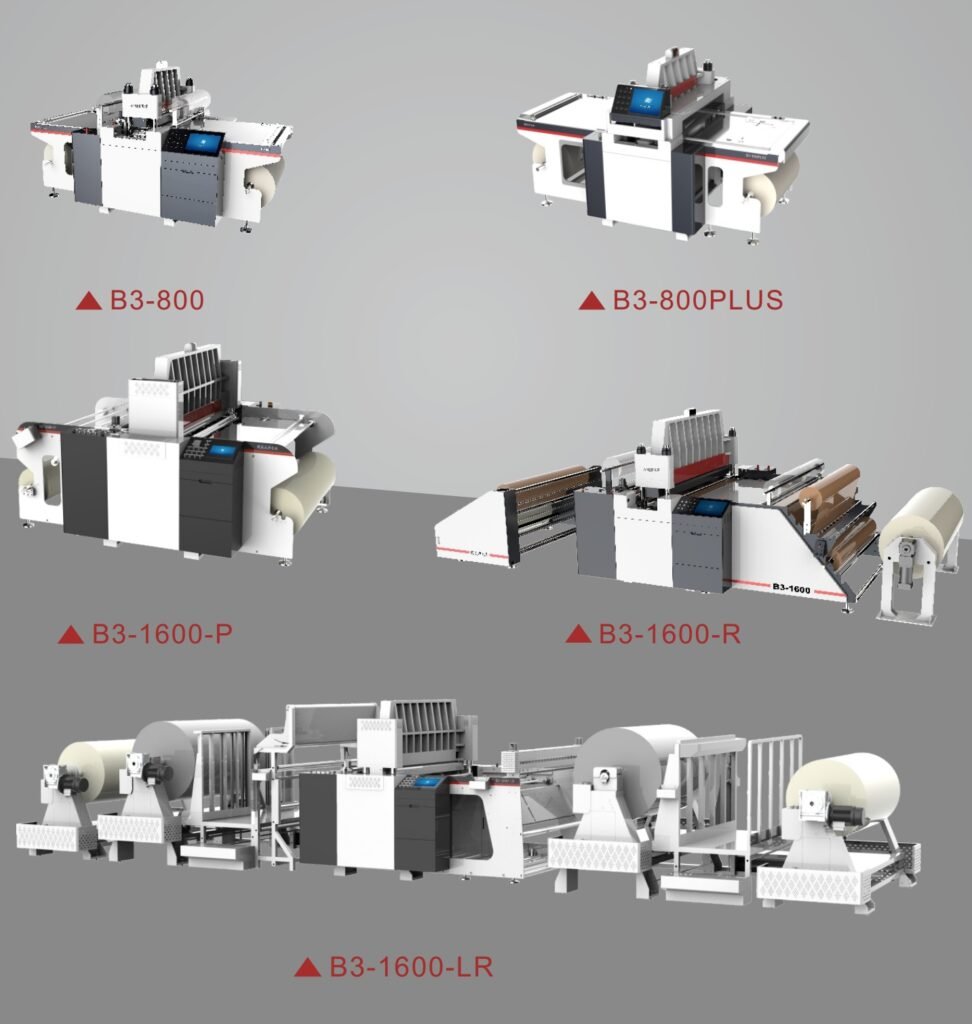

Leather Punching machine

For Furniture

In the furniture manufacturing industry, leather, as a high-end and comfortable material, is widely used in furniture products such as sofas, chairs, and beds. Leather punching machine and technology is one of the key processes to improve the aesthetics, breathability, and comfort of furniture.

Higher standard

How leather punching machine works

For punching of furniture leather, CNC leather punching machine is an ideal choice. It integrates CNC technology, automation technology and precision machinery technology, and can achieve efficient and accurate punching. CNC leather punching machine can automatically complete the whole process of pattern design, typesetting, positioning, punching, etc. through computer programming control, greatly improving production efficiency and processing accuracy.

Mould leather punching machine

Mould leather punching machine is a traditional punching equipment, mainly using the principle of mechanical stamping, through the rotation radius of the crankshaft to achieve mechanical reciprocating circulation, forming the function of stamping. This kind of equipment is easy to operate, easy to maintain and suitable for mass production. For the punching processing of furniture leather, the mechanical leather punching machine can efficiently complete the processing of various passes to meet the production needs

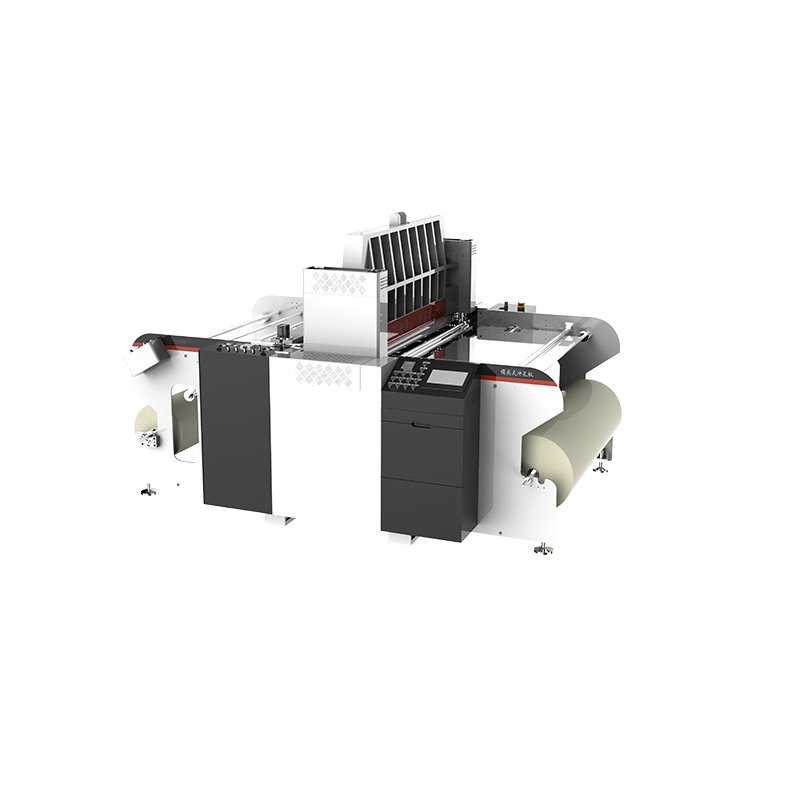

CNC leather punching machine

CNC leather punching machine represents the development direction of modern manufacturing technology. It integrates numerical control technology, electronic technology and software technology, and can realize automatic positioning, automatic typesetting, automatic scanning and other functions, accurate position, simple and convenient control. For shoe leather requiring complex patterns or small batch custom production, CNC leather punching machines have significant advantages.

Prepare leather material

Place the furniture leather to be punched on the workbench of the punching machine and fix it in place. According to the design requirements, select the appropriate punching die or set the CNC program/laser parameters.

Setting parameters

According to the material, thickness and hardness of the leather, adjust the processing parameters of the punching machine or laser punching machine, such as punching pressure, speed, laser power, focal length, etc. Set the number, spacing, arrangement and pattern of punching holes.

Start leather punching machine

Start the punching machine or laser punching machine, perform trial punching or trial punching, and check whether the hole shape meets the design requirements. After confirmation, perform batch punching.

Inspection and sorting

After punching, check whether the holes on the leather are neat, burr-free, and burnt-free. Finish the punched leather and prepare for subsequent processing or assembly.

Learn more about furniture leather punching machine customization service

Trusted By

Branded Partners

Anze Latest News

With an experienced and skilled team, we are familiar with all kinds of material characteristics and processing technology, and can customize perforating leather Machine according to customer needs. Any questions please contact us! Whatsapp +86 180 0298 0031

How to install and maintain the machine?

Some models are shipped assembled in the factory. Large equipment is packaged in several parts and an installation manual is provided. All equipment is equipped with user manuals in Chinese and English.

Customers can send someone to anze factory to learn or we send technical experts to provide on-site training

What are the machine working environment requirements?

The CNC Leather Punching Machine should be fixed on a stable table and the environment should be kept clean and tidy to avoid contact with dust, static electricity, humidity, and chips to cause parts failure.

How is your after-sales policies?

We have an experienced after-sales team 24h online service and a completafter-sale system. Factory trainning support, Video technical available to service machinery overseas. support, online support, Engineers.

Are you available for on-the-spot invitation?

Of course we do welcome to visiting our company and have a face-to-face communication to advance mutual business.

What's the delivery time?

Lead time varies depending on the order quantity and customization, typically ranging from 7 to 10 working days.If it is a custom leather punching machine order, it takes 1-2 months.