APPLICATIONS

experience to be trusted

Leather Punching machine

For Automotive Interior

With the rapid development of the automobile industry and the diversification of consumer demand, the interior design of automobiles is paying more and more attention to individuation, comfort and aesthetics. Among them, punching technology, as an important processing technology, is widely used in the processing of automotive interior materials, which brings more innovative possibilities for interior design.

Since 2005, Anze focus on the development and manufacture of leather punching machine.

We are committed to providing our customers with better leather punching solutions by Anze higher R&D Capabilities!

widely used

Leather punching machine in the automotive interior industry

Auto door panel

Audio cover leather

Steering wheel

Leg support

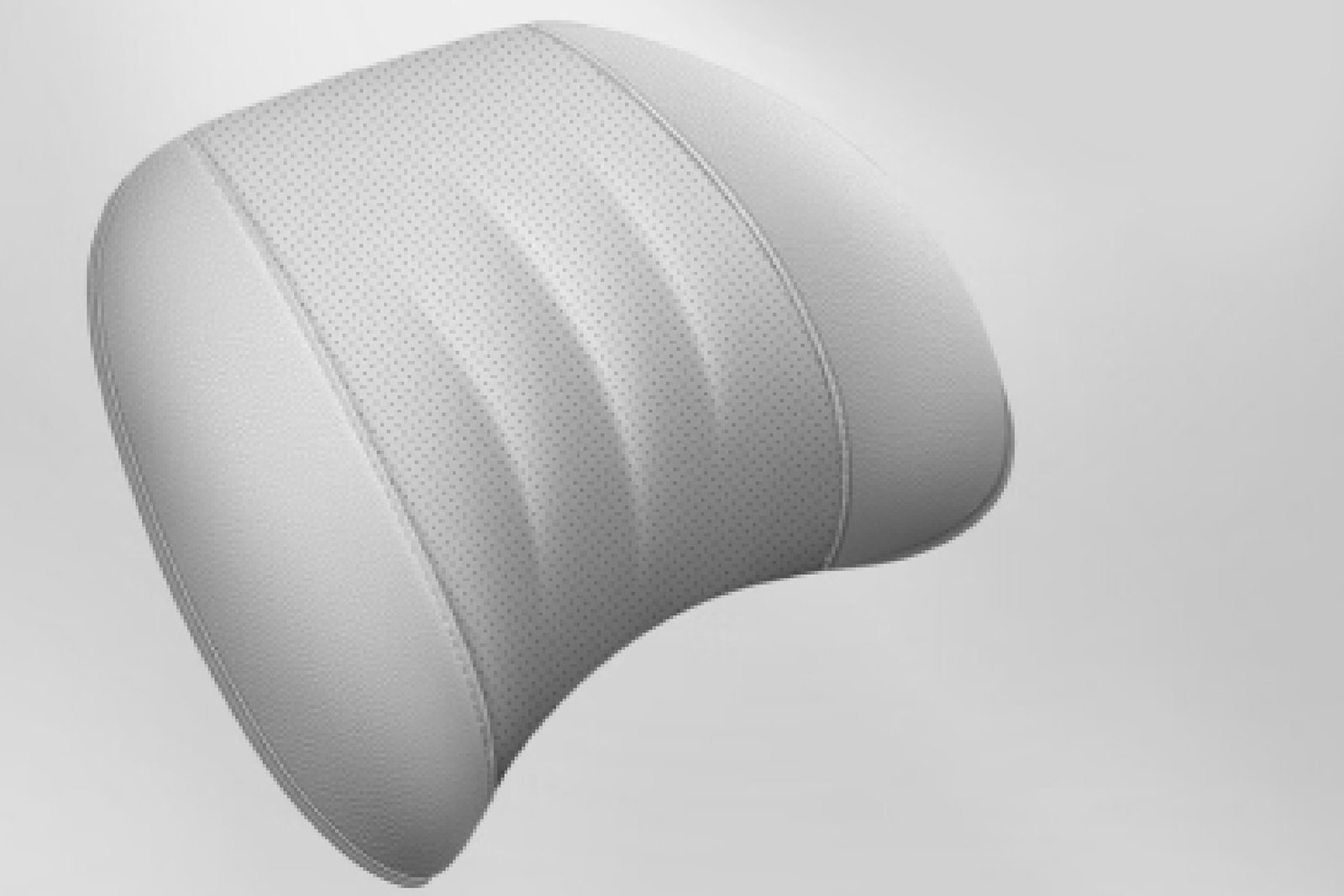

Headrest

Backrest

Seat cushion

Car Headrest leather punching machine

Car headrest as a driving comfort configuration supplies and safety protection products, its original design is not only to provide comfort, but in the vehicle rear-end or other types of collision, play a role of cushioning and support to protect the head and neck of the driver and passenger. When a vehicle encounters a rear-end collision, due to inertia, the human body naturally tilts backward, and the neck and head will bear the tremendous pressure brought about by the acceleration or deceleration of the vehicle. The headrest is designed to relieve this pressure, act as a buffer and support, and reduce the risk of head injury for drivers and passengers.Anze leather punching machine can punch holes for the car headrest, which is conducive to the rapid exchange of air in the headrest to ensure the shape of the headrest.

Car Backrest leather punching machine

Leather car seats have many advantages. Easy heat dissipation is one advantage. The leather punching machine can punch a lot of holes for the seat, which is not only beautiful, but also can quickly dissipate heat.

Steering wheel leather punching machine

Non-slip is the most important feature of the steering wheel cover. The steering wheel cover is perforated, which is conducive to absorbing sweat, enhancing the friction between the hands and the steering wheel, and is more conducive to anti-slip.

Experience the perfect leather punching machine customization service

Trusted By

Branded Partners

With an experienced and skilled team, we are familiar with all kinds of material characteristics and processing technology, and can customize perforating leather Machine according to customer needs. Any questions please contact us! Whatsapp +86 180 0298 0031

How to install and maintain the machine?

Some models are shipped assembled in the factory. Large equipment is packaged in several parts and an installation manual is provided. All equipment is equipped with user manuals in Chinese and English.

Customers can send someone to anze factory to learn or we send technical experts to provide on-site training

What are the machine working environment requirements?

The CNC Leather Punching Machine should be fixed on a stable table and the environment should be kept clean and tidy to avoid contact with dust, static electricity, humidity, and chips to cause parts failure.

How is your after-sales policies?

We have an experienced after-sales team 24h online service and a completafter-sale system. Factory trainning support, Video technical available to service machinery overseas. support, online support, Engineers.

Are you available for on-the-spot invitation?

Of course we do welcome to visiting our company and have a face-to-face communication to advance mutual business.

What's the delivery time?

Lead time varies depending on the order quantity and customization, typically ranging from 7 to 10 working days.If it is a custom leather punching machine order, it takes 1-2 months.